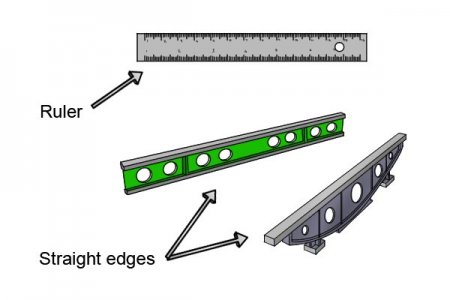

Advice and comments. please. I just watched a video of an Australian guy making a wooden saw guide to keep his cuts straight. That's quite common on YouTube. What caught my "metalworking" eye was that he used as a reference, a straightedge he obviously acquired somewhere (but doesn't refer to in his video, and no comments at all about it either). Certainly it must have been hollow, and looked to be perhaps 1" x 3" tubing - might be aluminum. At least 6 feet long. So, the question is - if someone needed a decent straightedge made from metal, what's the best way to get there? For the record, many years ago, I bought a 9 foot long cold rolled piece of steel, 2" x 3/8" and had it ground to make it as straight as reasonably possible - for a local sharpening establishment anyhow. The trouble with that is that when I lay it out to use it and secure both ends, I can easily move the middle about 1/32" each way - so it is not as accurate as I want.

For the record, I am not looking to get anywhere close to perfection with this. But +/- 1/32" over 9 feet is not acceptable either. Has anyone made or bought anything close to a decent long straightedge? I have a couple of decent straightedges from Lee Valley, but they top out at 36". Something I might use on an 8-foot sheet of plywood?

For the record, I am not looking to get anywhere close to perfection with this. But +/- 1/32" over 9 feet is not acceptable either. Has anyone made or bought anything close to a decent long straightedge? I have a couple of decent straightedges from Lee Valley, but they top out at 36". Something I might use on an 8-foot sheet of plywood?