johnnielsen

John (Makonjohn)

Anyone aware of any steel spiral stair suppliers or manufacturers in the Calgary area?

All I can add to this thread is negativity and terror. Please feel free to not read the rest of my post.

My parents had a metal spiral staircase built for their cottage in order to conserve space.

It was a permanent accident waiting to happen. Nobody was immune. Everyone who ever visited got skinned shins, skinned calves, or worse. You eventually learned to go up/down with both feet on each step one at a time and you never used those stairs in the dark. Everyone hated them.

I think spiral stairs have to be huge (say 5ft wide - 11 altogether) to work well.

Jeeez i was thinking a spiral stair case would be great, then realized i ain't getting any younger and a elevator would be a better option for my knees.

I can relate. My mother-in-law has a set of homebuilt steel spiral stairs to the loft of her log home that would make most people shutter. She typically has gone up them like a billy goat carry stuff in her arms at the same time. Now that she is 90 years old we have finally gotten a bit more nervous about her doing so considering the lack of safety rails and guards. I have addressed some of those concerns with some sort of temporary fixes but they still make me nervous.All I can add to this thread is negativity and terror. Please feel free to not read the rest of my post.

My parents had a metal spiral staircase built for their cottage in order to conserve space.

It was a permanent accident waiting to happen. Nobody was immune. Everyone who ever visited got skinned shins, skinned calves, or worse. You eventually learned to go up/down with both feet on each step one at a time and you never used those stairs in the dark. Everyone hated them.

I think spiral stairs have to be huge (say 5ft wide - 11 altogether) to work wel

Last I looked Home depot had a pretty good selection of spiral cases they could order. Prices are crazy high for the things but I have no idea if Home Depots prices are competitive.Anyone aware of any steel spiral stair suppliers or manufacturers in the Calgary area?

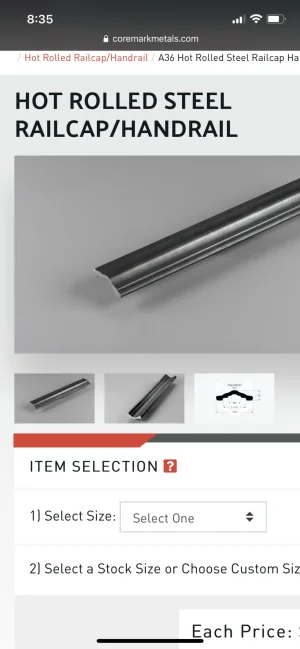

I’d be interested in how the handrail was made. This is the part that kinda stymies me when I think about building one.I’ve built several.

I used to work for an old school Italian guy doing fences railing and gates etc.

If laid out properly they are functional and not too trippy. You want the Center of the tread to be your typical rise/run and work from there.

We would use a Center post ~3.5” and a larger section that slipped over with each tread attached. Outdoor or all metal ones we would figure the size and get a local big shop to bend the tread pans out of checker plate. I’d you want wood a frame of angle iron could be made.

Once did a two story one in a converted church made into a house, that lone was pretty sweet!

What ever you do DO NOT!!!!

Order a build it yourself kit. They are expensive junk. More then a few times he would quote people a price. They would order the “cheaper” kit and then hire us to fix and rebuild it properly at close to the cost of what the original build would have been.

Want to make one again for myself one day when I have a place for it.

Just built a set a ultra steep ‘soldier’ stairs for buddy who was flipping a house. Now THAT IS A TRIPPY STAIR!! 9foot of rise in less then 5’!!

Yes the hand rail is the a tricky part, well unless you’ve got a rolling machine.I’d be interested in how the handrail was made. This is the part that kinda stymies me when I think about building one.