Downwindtracker2

Ultra Member

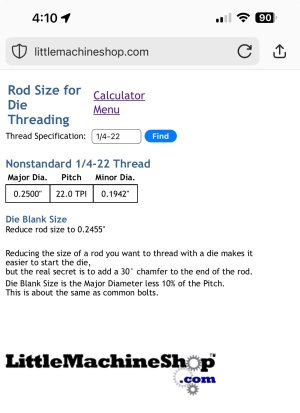

I was making some inletting pins for glass bedding three different systems. One end is threaded to match the target system and the other end 1/4' UNC for a wing nut , both sets are 1/4". The 1/4"x 32tpi, a special fine, went great. Both dies are KBC house brand made in Poland. However, KBC doesn't sell anything for a 1/4" x 22 Whitworth, so I had to order from Brownells. The Brownell one was a made in China. Twice I ended up with a badly cocked thread. At work I've hand threaded enough, that I have even worn out a die. It was hard starting so for the second attempt I really tapered the lead in. I'm out of 1/4" CRS now. Any tricks for when pick up some more rod?

Before suggesting threading on the lathe, I have never threaded on a lathe before and I would need to make a Whitworth tool bit. My lathe has a 8" chuck and is bit clumsy.

Before suggesting threading on the lathe, I have never threaded on a lathe before and I would need to make a Whitworth tool bit. My lathe has a 8" chuck and is bit clumsy.

Last edited by a moderator: