pdentrem

Ultra Member

My micrometer was getting stiff and it came down to the roller lock.

So, I removed the lock using a small jeweler’s screw driver.

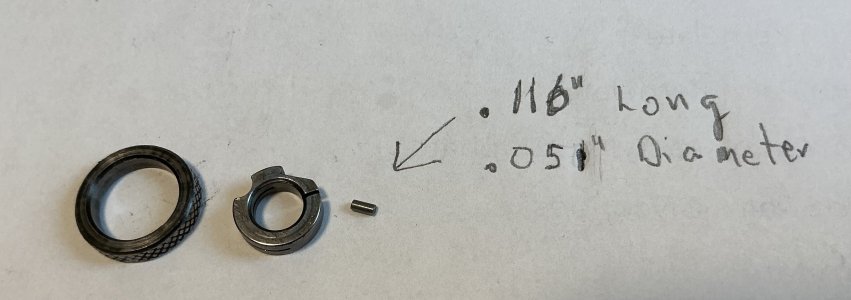

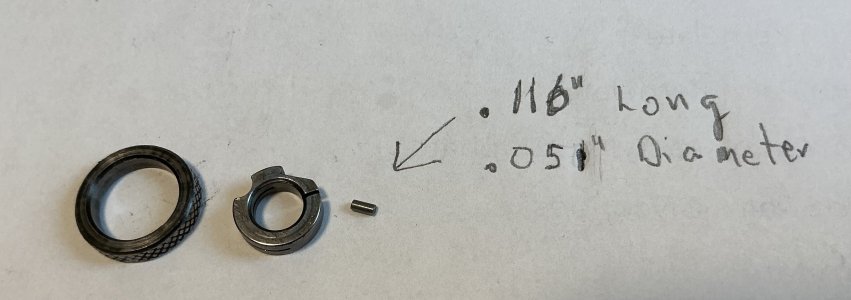

It is made of 3 pieces.

The tiny pin and the split ring is the lock. The ring was closed with no gap. I opened the gap a bit.

The little pin was measured for future need.

Put the lock back together and installed everything back in the frame. Note that there is a tab that the lock ring has to align with. Marked in red circles.

Carefully align the center to the frame to allow the spindle to pass through.

If one feels the thimble a bit loose, one can tighten the collet by turning the collar with hole a bit. The mic can be set to read zero by turning the whole sleeve by the other hole.

So, I removed the lock using a small jeweler’s screw driver.

It is made of 3 pieces.

The tiny pin and the split ring is the lock. The ring was closed with no gap. I opened the gap a bit.

The little pin was measured for future need.

Put the lock back together and installed everything back in the frame. Note that there is a tab that the lock ring has to align with. Marked in red circles.

Carefully align the center to the frame to allow the spindle to pass through.

If one feels the thimble a bit loose, one can tighten the collet by turning the collar with hole a bit. The mic can be set to read zero by turning the whole sleeve by the other hole.