The SM1340s (and perhaps other models with the same feed mechanism) are notorious for hard feed disengagement forces. The pucker factor goes right up, especially when feeding to a shoulder.

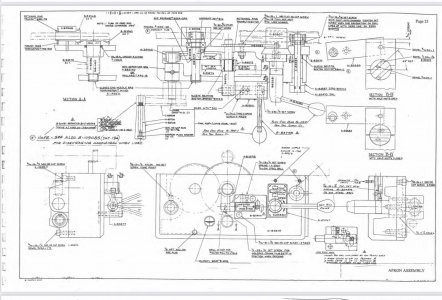

Refer to page 25 of the manual.

View attachment 19383

The reason is the design: the engagement/disengagement is by means of axial movement of two spur gears into/out of mesh. The longitudinal feed gear becomes heavily loaded because of the gear ratio; the engagement lever has a poor mechanical advantage because of its short throw (22* up). Any kind of wear on the sleeve bearing will cause the feed gear to become harder to disengage under load because it can “cock” slightly sideways or bind up on its shaft.

I would disassemble the apron and check everything. Replace the sleeve bearing if it is worn even a bit. Deburr all gear teeth. Make sure the feed gear shaft is moving really freely in and out. Keep it well lubed by its oiler on the front of the apron after re-assembly.

A technique that works really well as far as the operation of the feed system (both long and cross) on these lathes:

a) to engage:

move the lever slowly and “feel” for the engagement while you manually move the carriage (or cross slide) in the desired direction of the feed. Ideally, you move it at the same speed that it will auto-feed after engagement. You basically synchronize the gears manually (like sifting a non-synchromesh gearbox) prior to engagement. It is quite easy to feel on the feed lever as the gears come into mesh and the lever moves like butter through the full length of travel (full up or down).

b) to disengage:

pick up the carriage movement (or cross slide) with the hand wheel in the direction of travel. “Over run” the feed rate to unload the feed gears and disengage the feed handle. The force will be next to nothing if you are synchronized with your movements.

The cross feed is not nearly as bad as the longitudinal feed for “binding up” (the gear ratio is different and there is less mass to move).

You always want full travel of the feed lever to ensure the full width of the feed gear is engaged. Partial engagement puts a huge load on a small section of gear tooth and only makes the problem worse in the long run.

Feed engagement/disengagement forces were/are a known issue for lathe designer. They went to considerable lengths to mitigate the problem. One way designers solved the problem was with the use of a worm gear/worm wheel combo. The worm can be ”separated” from the wheel under any load with little force because of the gear tooth geometry. Colchester uses such a system.

Another way to mitigate the problem is to use two saw toothed gears meshing axially (CMT Ursus).

A dog clutch (Hardinge, I think) or a friction clutch could also be used. I think Monarch and some of the SM Utilathes use the multi disc friction clutch system.