Hello All,

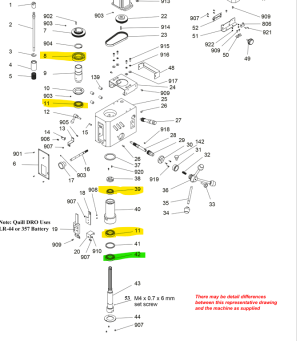

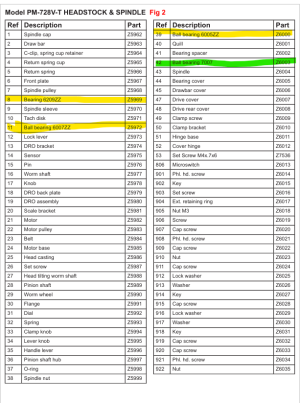

My PM728 spindle recently started making high frequency screeching noise that mainly happens at speeds above 2000 RPM but recently also at lower RPMs. The sound is not coming from the belt or motor (disconnected and replaced the belt with a brand new one to isolate the sound) and PM tech support are telling me this doesn’t sound like the bearings. Wanted to get a second opinion because it does sound like a bearing issue to me. Video linked below:

My PM728 spindle recently started making high frequency screeching noise that mainly happens at speeds above 2000 RPM but recently also at lower RPMs. The sound is not coming from the belt or motor (disconnected and replaced the belt with a brand new one to isolate the sound) and PM tech support are telling me this doesn’t sound like the bearings. Wanted to get a second opinion because it does sound like a bearing issue to me. Video linked below: