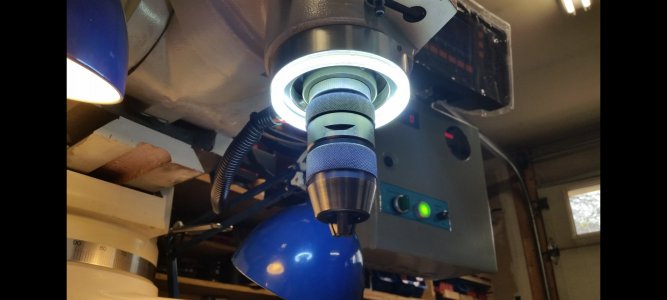

Something that has annoyed me about my new mill is the handle for the spindle lock is only 1.25" long. I have to really crank on it to make the spindle lock tight enough so the power drawbar doesn't move the spindle down when tightening a collet

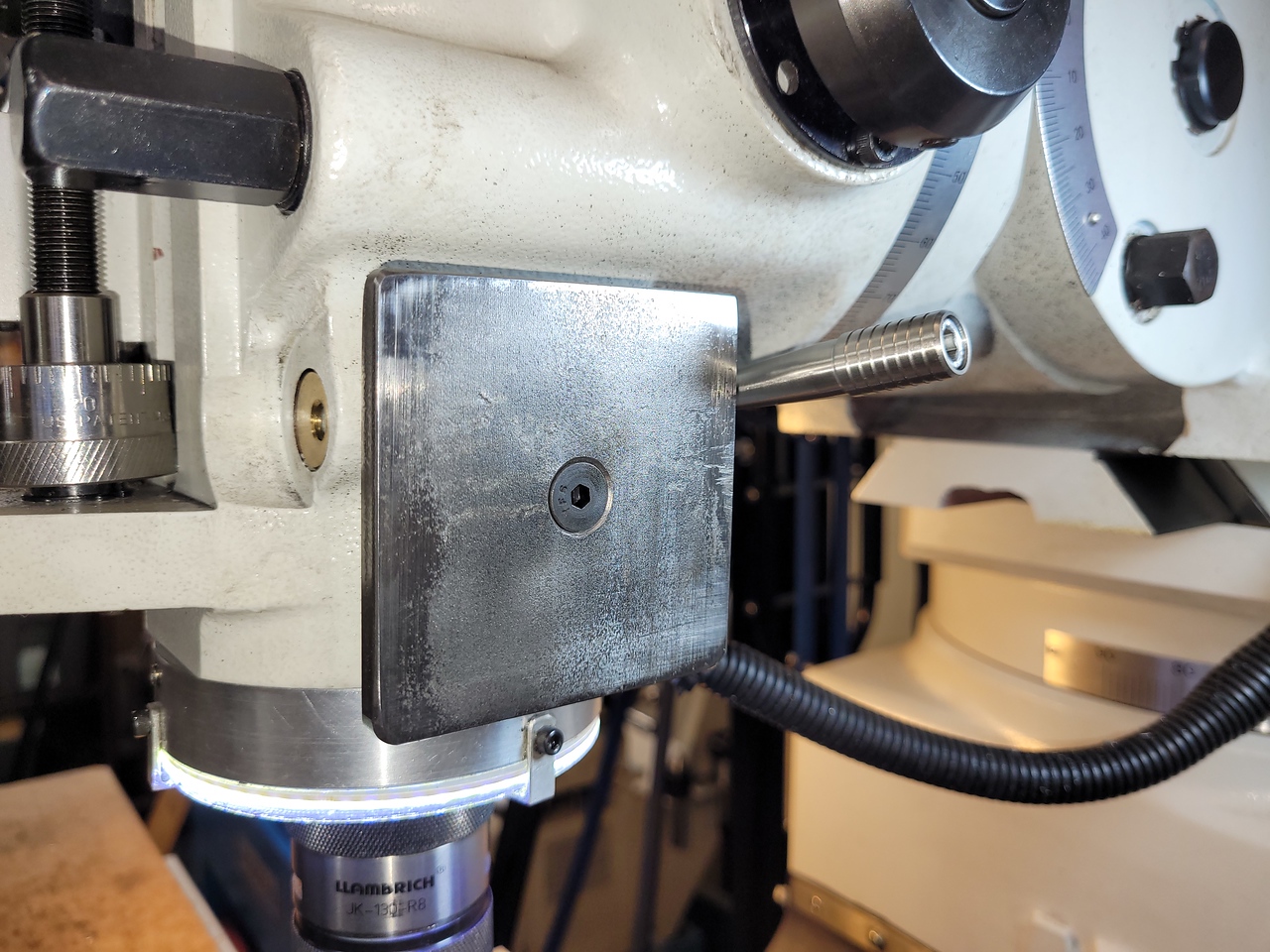

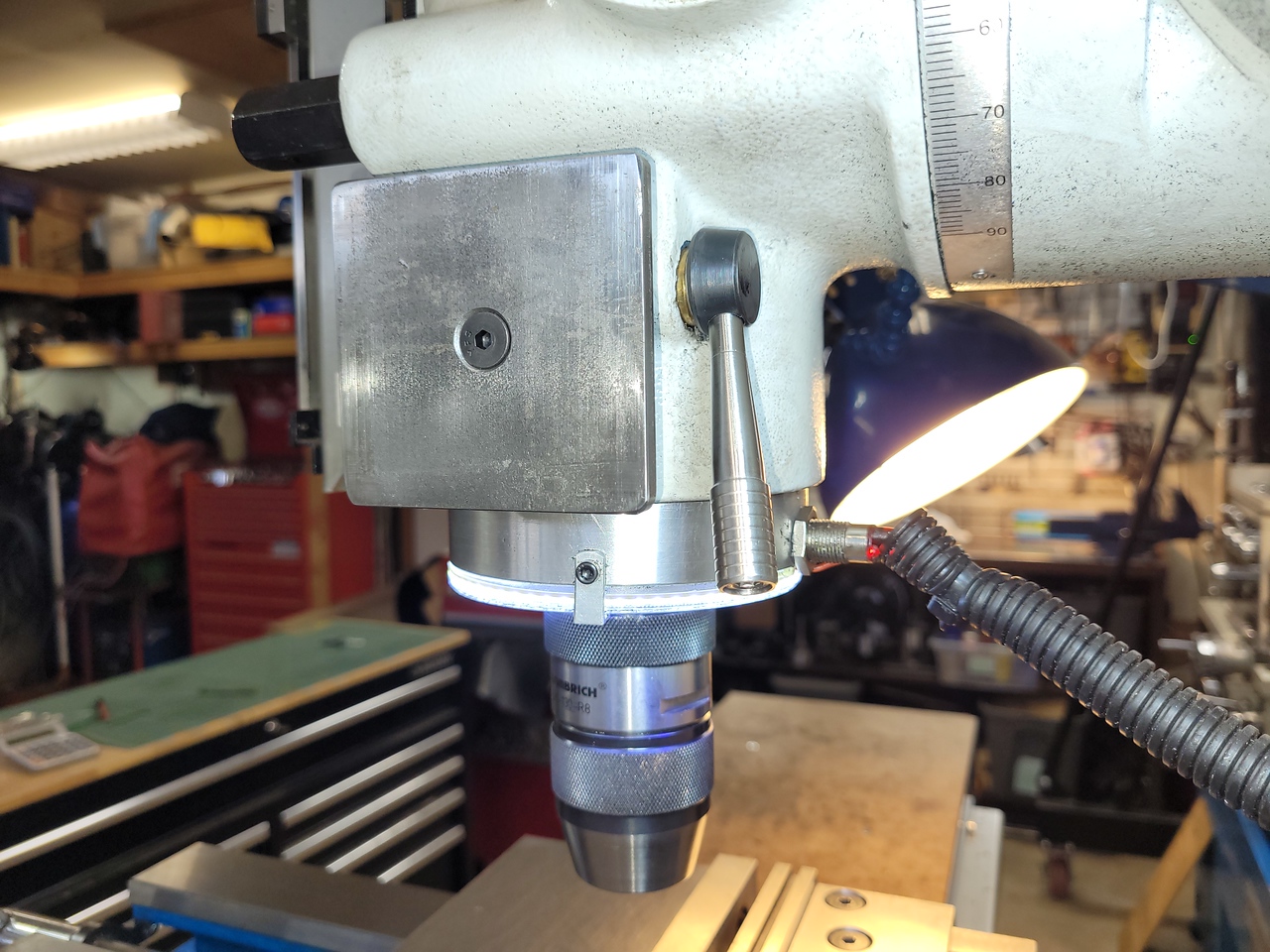

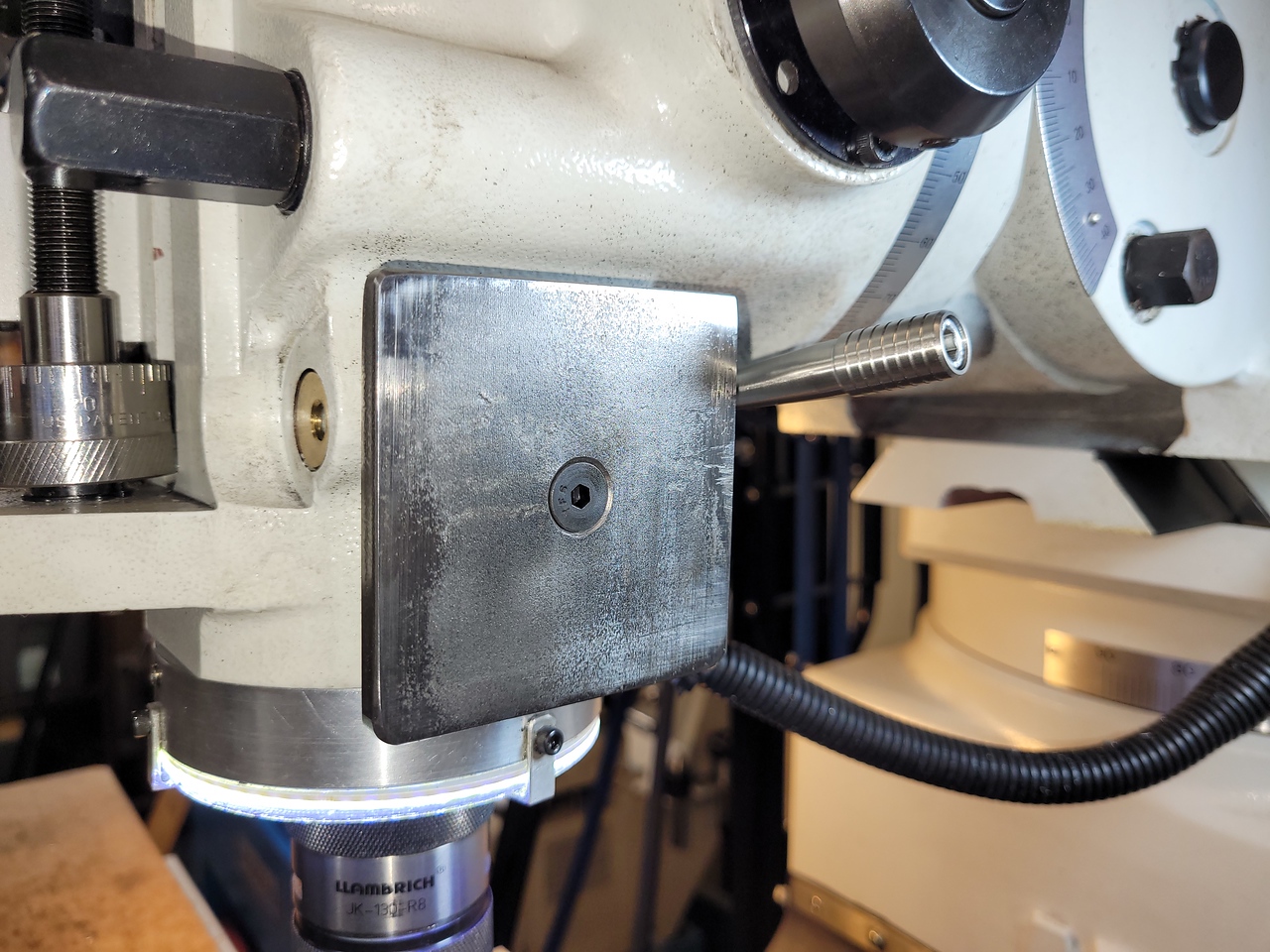

I also wanted to move the handle to the rear of the head so the default position due to gravity is unlocked instead of locked as it is when the handle is on the front. I have a 3" X 3" square plate mounted next to the spindle lock to mount a magnetic indicator base on, that made it very difficult to work with the short handle.

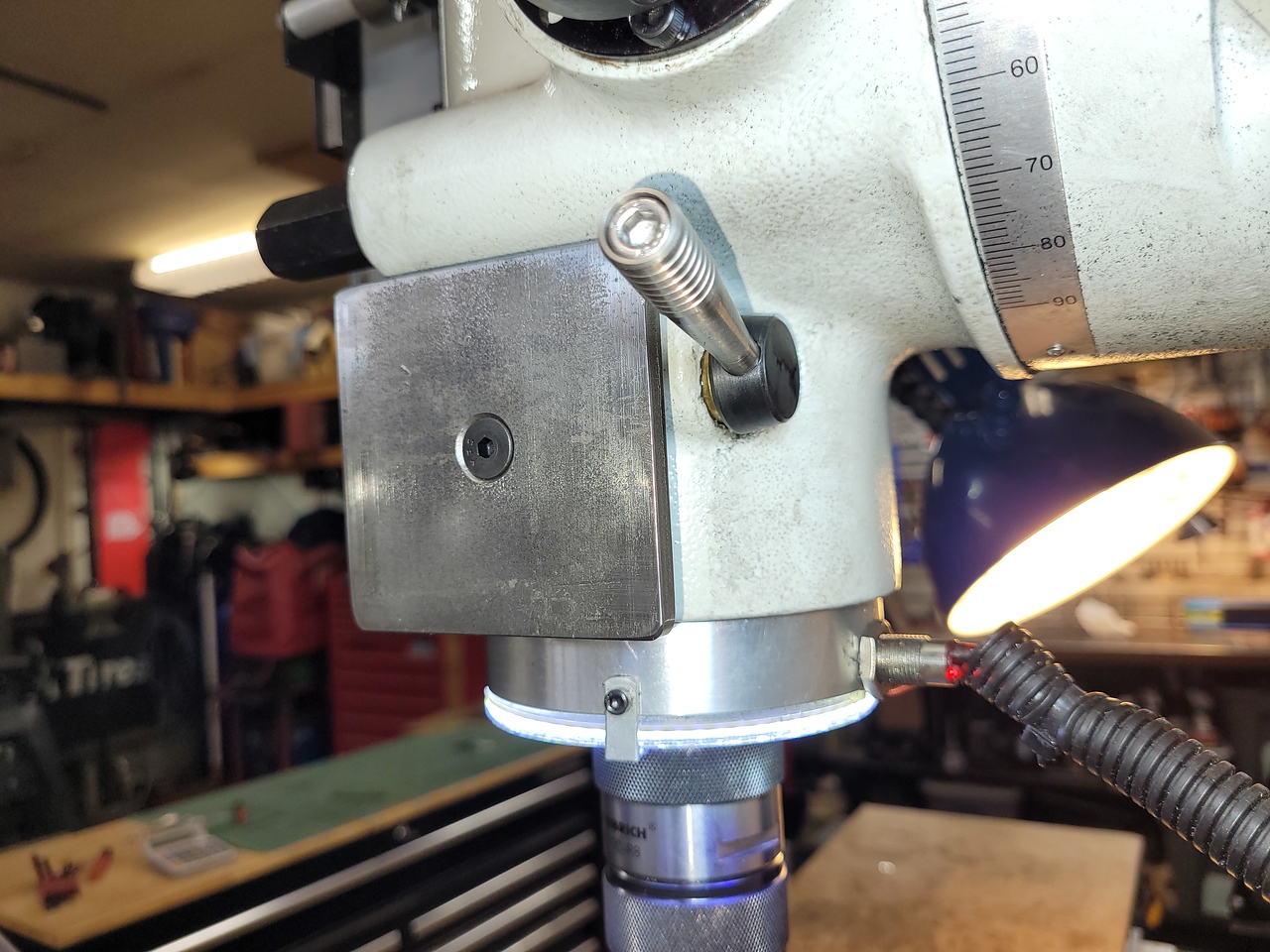

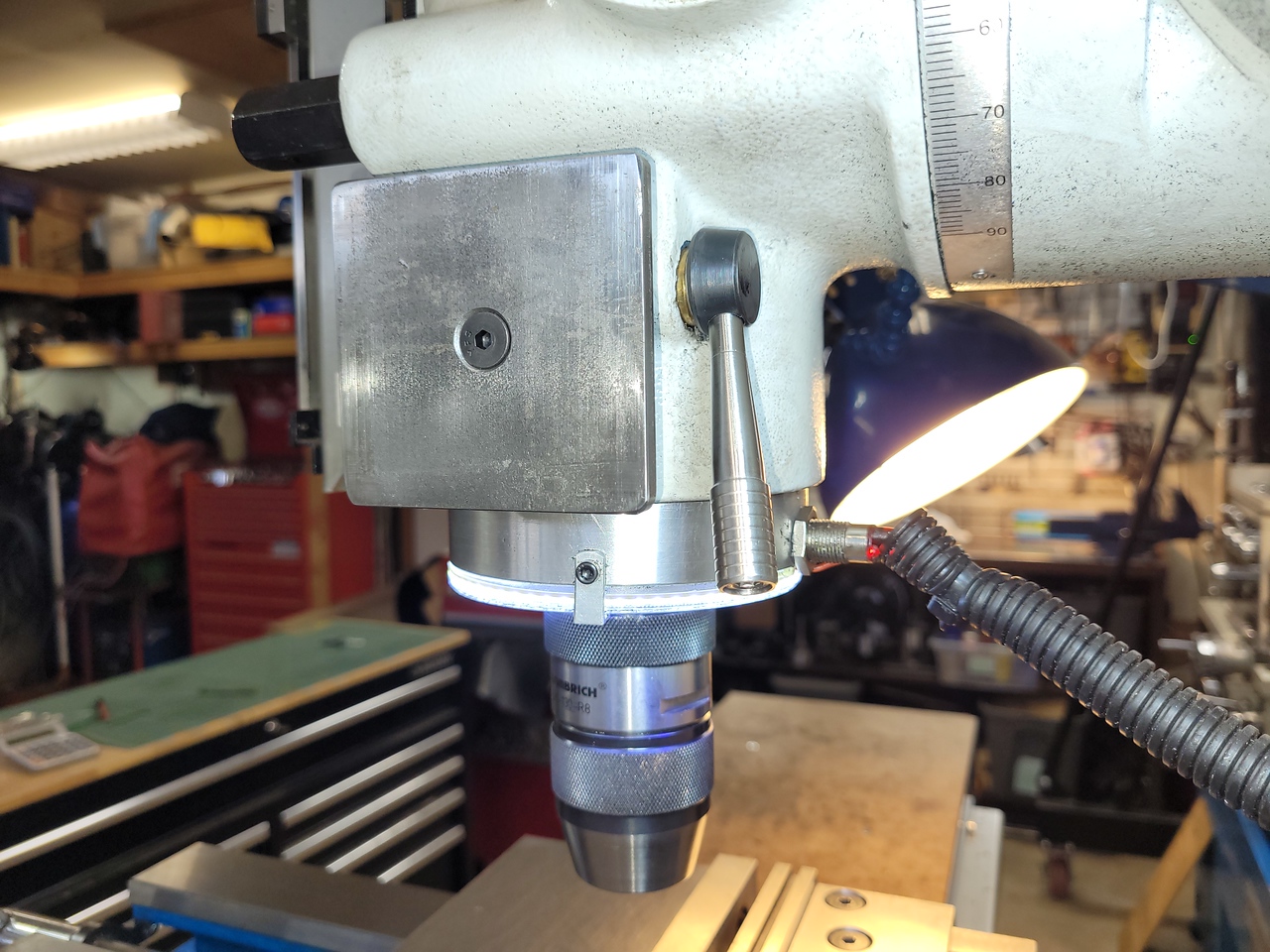

I made up the 5/16" X 3" threaded shaft with a short piece of 1" CRS with a pocket for the head of the bolt, then welded the bolt in place and machine the end flat again. The handle is made from a short length of 1/2" 303 stainless and a M6 stainless socket head screw. Huge improvement! This cold snap has me looking for excuses to stay home and deal with my small project list.

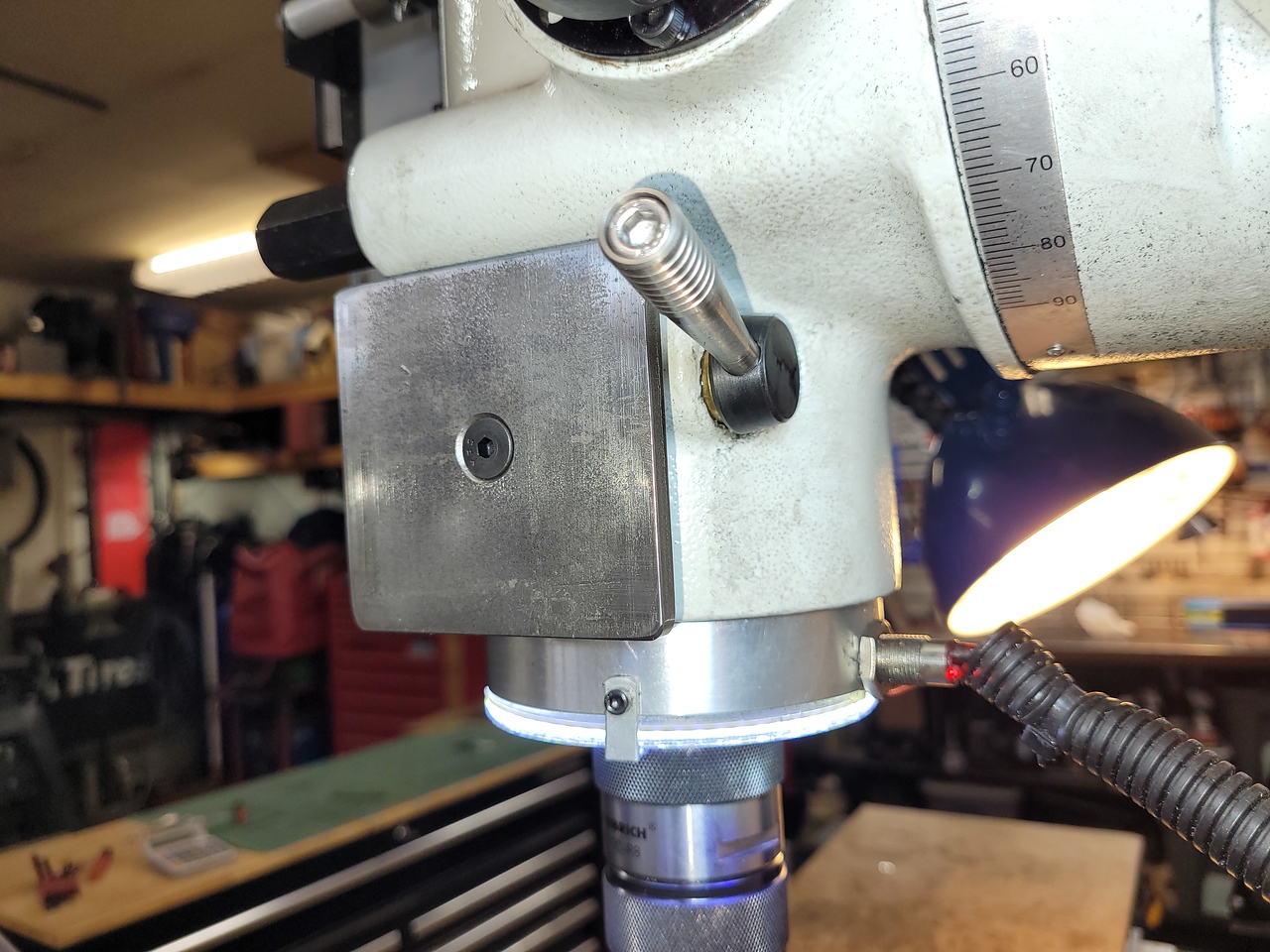

I used Birchwood Casey cols blue to blacken the top of the shaft and as you can see here the welded top part turned out splotchy. Oh well, no one will know except me.

I also wanted to move the handle to the rear of the head so the default position due to gravity is unlocked instead of locked as it is when the handle is on the front. I have a 3" X 3" square plate mounted next to the spindle lock to mount a magnetic indicator base on, that made it very difficult to work with the short handle.

I made up the 5/16" X 3" threaded shaft with a short piece of 1" CRS with a pocket for the head of the bolt, then welded the bolt in place and machine the end flat again. The handle is made from a short length of 1/2" 303 stainless and a M6 stainless socket head screw. Huge improvement! This cold snap has me looking for excuses to stay home and deal with my small project list.

I used Birchwood Casey cols blue to blacken the top of the shaft and as you can see here the welded top part turned out splotchy. Oh well, no one will know except me.