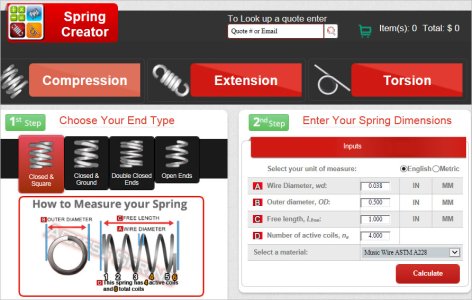

Hey guys, I am trying to track down a spring that works for expanding ( to push things away from each other) -- compression spring?

It needs to fit a rod down the middle, 1/2"-3/4" or so. Somewhere in there.

Should be about 2" long (or longer so I can cut it) and should be kinda beefy, enough to lift 5 or 10 lbs.

And I need two!

Where does everyone source their springs?

JW

Sent from my iPhone using Tapatalk

It needs to fit a rod down the middle, 1/2"-3/4" or so. Somewhere in there.

Should be about 2" long (or longer so I can cut it) and should be kinda beefy, enough to lift 5 or 10 lbs.

And I need two!

Where does everyone source their springs?

JW

Sent from my iPhone using Tapatalk