calgaryguy

Chris

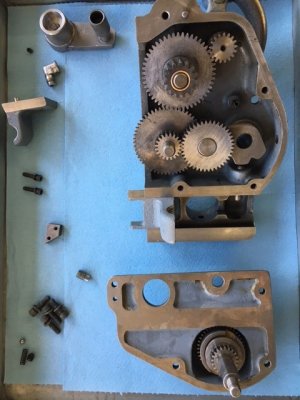

So I got way ahead of myself and didnt take pics of the disassemble of the apron on my SM9

Here's where I am at. Lots of brake cleaner and lacquer thinner was used. I didnt need those brain cells anyways...

There was a significant amount of old black gunk coating everything. I should have taken pics of the parts pan after I spent 3 hours cleaning and inspecting. No chipped teeth, all gears spin freely on their shafts but no excessive wear, etc. Off to get some rtv to seal it back up...

Here's where I am at. Lots of brake cleaner and lacquer thinner was used. I didnt need those brain cells anyways...

There was a significant amount of old black gunk coating everything. I should have taken pics of the parts pan after I spent 3 hours cleaning and inspecting. No chipped teeth, all gears spin freely on their shafts but no excessive wear, etc. Off to get some rtv to seal it back up...