trlvn

Ultra Member

Just wanted to share a helpful resource on slitting saws:

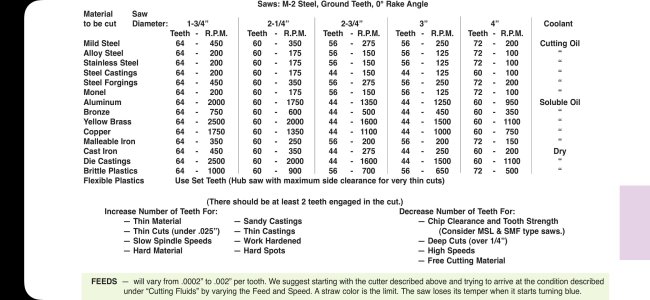

Pages 13 and 14 have a bunch of good information including a table of recommended rpms based on the blade diameter and material to be cut. They also suggest that the feed rate can be up to 2 thous per _tooth_! Not sure I'll ever push things that hard. I keep a copy of this page with my blades.

YMMV,

Craig

Pages 13 and 14 have a bunch of good information including a table of recommended rpms based on the blade diameter and material to be cut. They also suggest that the feed rate can be up to 2 thous per _tooth_! Not sure I'll ever push things that hard. I keep a copy of this page with my blades.

YMMV,

Craig