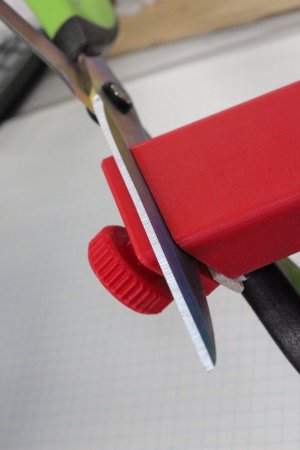

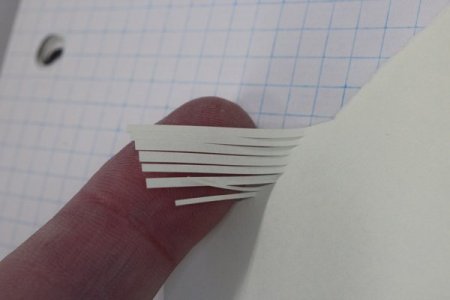

HaHa just kidding. Might be a bit premature. OTOH my 3DP FrankenSharpener prototype for shop scissors works amazingly well. Using my 1x42 Delta belt sander with a worn out (and too coarse) blue belt. Once clamped its very easy to just guide it along the table. It put a very constant, consistent bevel on the edge. My well abused Oldy's have been hand ground by yours truly so no surprise to see edge correction there. But I pre-felt penned some new-ish offshore office type scissors & it was obvious my grind was better. Bit of edge de-burring with diamond & they cut like the dickens. I kind of mucked up the clamp design & it has no angle variation (yet). Probably there is more to scissor edges than what I'm doing. I won't volunteer to do the wifes sewing shears. But for my shop stash, I'm happy

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

Tips/Techniques Short Tormek Stock!

- Thread starter PeterT

- Start date

Tips/Techniques