I don't like shaking rattle cans. Some auto paint cans I have say to shake for at least 1 minute. That seems like about seventeen hours to me. So I designed and printed a bunch of parts to turn rotational motion into linear motion to shake cans. That's picture 1 below. It worked for maybe 2 cans before it shook itself apart. So I thought about making the parts bigger, thicker, print with nylon etc. ok I could do that. What else is there? - and I found this guy on youtube who makes a spinning thing instead that you stick in your drill. Spin your paint cans with the drill instead of shaking. Seemed dubious to me but his video was convincing especially when he shows oil and water mixing in his contraption in very short order. Scan to 6:14 to see the oil and water mix. Pretty much instant mixing of the mixture.

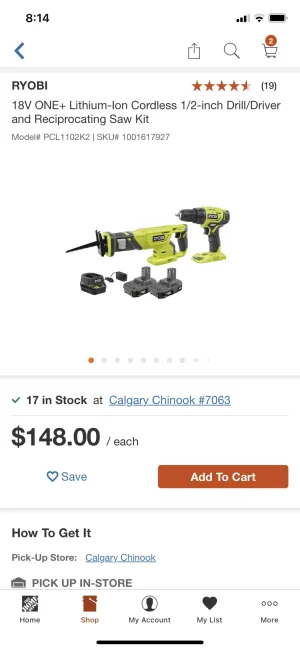

He uses some plumbing pipe and a pipe plug to fabricate his contraption. I'm 3d printing it. I don't want to buy 8' of 3" pipe I'll never use. People mention using an old food can - pretty quick to shove a bolt through one end I think. I think that would work if you also put in some fender washers on both sides and spun the drill a little slower.

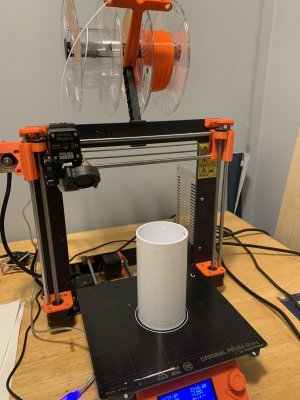

Back to my build. Picture two below shows the second attempt with 0.1" thick walls and bottom. That is a 1/4" nut with a big fender washer. It came apart testing on the second can but I am running it at full speed with the drill 1500rpm or so. The bolt is prone to bending and then it all came apart. I'm trying a 3/8" bolt on the next one.

Build 2 uses a 3/8" bolt and a 0.5" thick bottom plate printed with 70% infill and 17 perimeters. I also used a 0.8mm nozzle as I seem to be able to print much stronger parts with that approach. I'm still printing the final version and I'll post results.

He uses some plumbing pipe and a pipe plug to fabricate his contraption. I'm 3d printing it. I don't want to buy 8' of 3" pipe I'll never use. People mention using an old food can - pretty quick to shove a bolt through one end I think. I think that would work if you also put in some fender washers on both sides and spun the drill a little slower.

Back to my build. Picture two below shows the second attempt with 0.1" thick walls and bottom. That is a 1/4" nut with a big fender washer. It came apart testing on the second can but I am running it at full speed with the drill 1500rpm or so. The bolt is prone to bending and then it all came apart. I'm trying a 3/8" bolt on the next one.

Build 2 uses a 3/8" bolt and a 0.5" thick bottom plate printed with 70% infill and 17 perimeters. I also used a 0.8mm nozzle as I seem to be able to print much stronger parts with that approach. I'm still printing the final version and I'll post results.

Attachments

Last edited: