slow-poke

Ultra Member

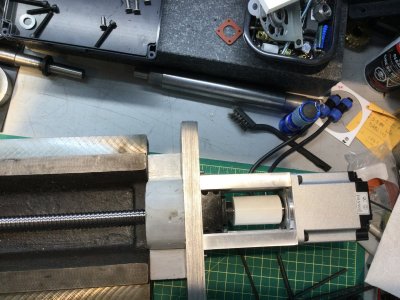

I'm getting close to wrapping up the mechanical aspect of the CNC conversion of my knee mill. I have two different style shaft couplers and both will require a little tweak to my motor mount to make fit.

The long one is about 1/8" too long to fit my existing bracket, so I would need to either:

Use the long coupler and

a) machine about 1/8" off the leading edge of the face of the ballscrew (the edge that mates against the bearing) or

b) shorten the bearing spacer that fits in the bearing block by 1/8", the spacer appears to be hardened.

c) Use the short coupler (diaphragm style) and shorten my mounting block by about ~5/8"

The question is....... of these two style couplers is one better than the other (Stronger, more compliant etc.)?

The long one is about 1/8" too long to fit my existing bracket, so I would need to either:

Use the long coupler and

a) machine about 1/8" off the leading edge of the face of the ballscrew (the edge that mates against the bearing) or

b) shorten the bearing spacer that fits in the bearing block by 1/8", the spacer appears to be hardened.

c) Use the short coupler (diaphragm style) and shorten my mounting block by about ~5/8"

The question is....... of these two style couplers is one better than the other (Stronger, more compliant etc.)?

Last edited: