TorontoBuilder

Ultra Member

I am restoring a Meyrat and Louisoni Tousdiamant Mill, which utilizes a Golay Buchel motor and spindle that takes Schaublin W12 collets. As part of my restoration I like to research as much about the company's related to the machine as possible. I had thought that Golay and Buchel merely made the motor used in the milling machine, but it turns out not to be the case.

Golay Buchel was a swiss firm with a rich history in the swiss toolmaking industry, particularly for watch and jewelry making. They're perhaps most famous for making the favourite watchmakers precision lathes. Tony at lathes UK has this to say about Golay:

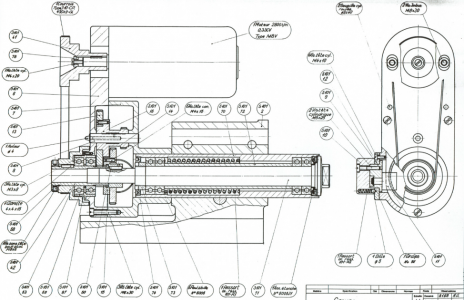

Golay later expanded and started manufacturing spindles which pretty much seem to be the spindle of choice for small precision swiss mills like the Aciera F1 and F2, the Sixis 101, and the Tousdiamants. The Aciera F1 and F2 had smaller 40mm diameter quills with needle roller bearings, while the Sixis and Tousdiamants had 55 and 60mm quills with angular contact bearings and a preload spring, thus making servicing of the spindle more rigid and easier to service. The Sixis 101 came with a high speed spindle is rated for up to 15k rpm.

This Tousdiamants pulley system does not look like it will yield such speeds from the 3300 rpm motor but I suspect that I can change out a pulley and safely obtain similar speeds from my spindle.

So of course I got to thinking, wouldn't this make a fine internal tool post grinder, with a few modifications such as a better spindle end shield to keep out grit, and huge block of cast iron for the mount?

I shall find out.

Golay Buchel was a swiss firm with a rich history in the swiss toolmaking industry, particularly for watch and jewelry making. They're perhaps most famous for making the favourite watchmakers precision lathes. Tony at lathes UK has this to say about Golay:

Manufactured by Golay-Buchel of Lausanne, Switzerland the "Favorite" lathes were but one part of a vast array of horological accessories turned out by the Company. Like Boley in Germany they offered a complete product range from the tiniest screwdriver through staking sets to micrometers, vernier gauges, precision drills, taps, dies, engraving machines and even electro-plating kits. Their 325-page catalogue was a treasure trove of mouth-watering items designed to help the watch and clock repairer undertake every conceivable task.

Golay later expanded and started manufacturing spindles which pretty much seem to be the spindle of choice for small precision swiss mills like the Aciera F1 and F2, the Sixis 101, and the Tousdiamants. The Aciera F1 and F2 had smaller 40mm diameter quills with needle roller bearings, while the Sixis and Tousdiamants had 55 and 60mm quills with angular contact bearings and a preload spring, thus making servicing of the spindle more rigid and easier to service. The Sixis 101 came with a high speed spindle is rated for up to 15k rpm.

This Tousdiamants pulley system does not look like it will yield such speeds from the 3300 rpm motor but I suspect that I can change out a pulley and safely obtain similar speeds from my spindle.

So of course I got to thinking, wouldn't this make a fine internal tool post grinder, with a few modifications such as a better spindle end shield to keep out grit, and huge block of cast iron for the mount?

I shall find out.