MecGen

Member

Hello friends

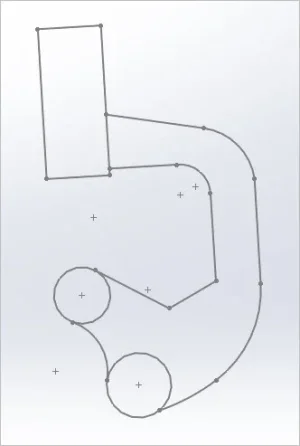

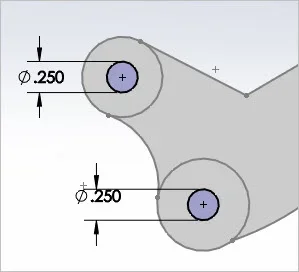

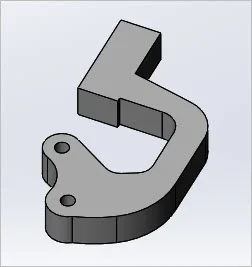

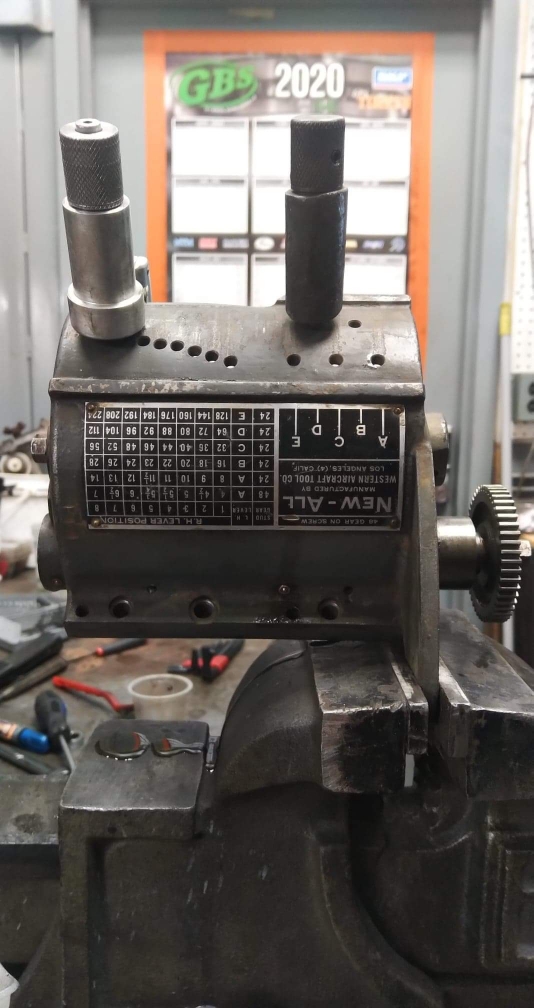

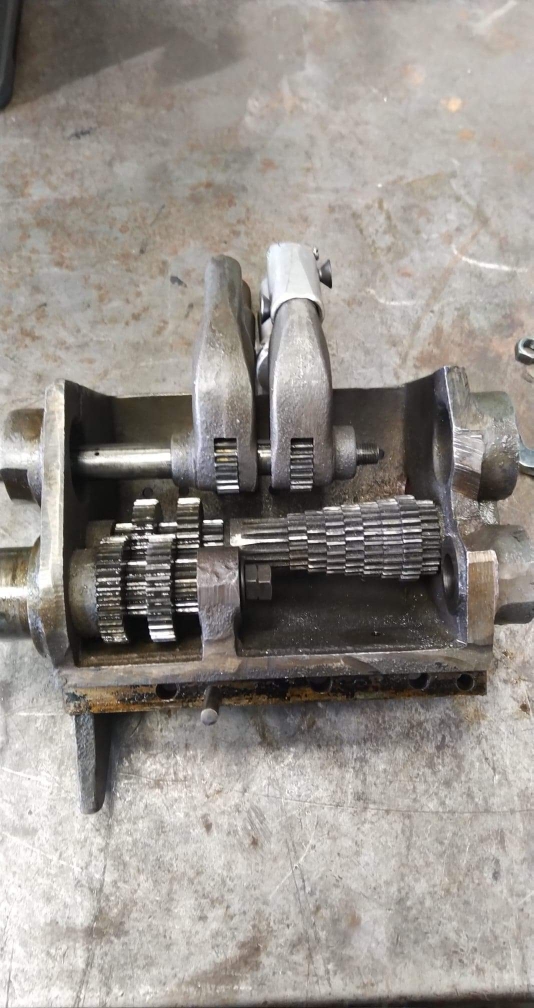

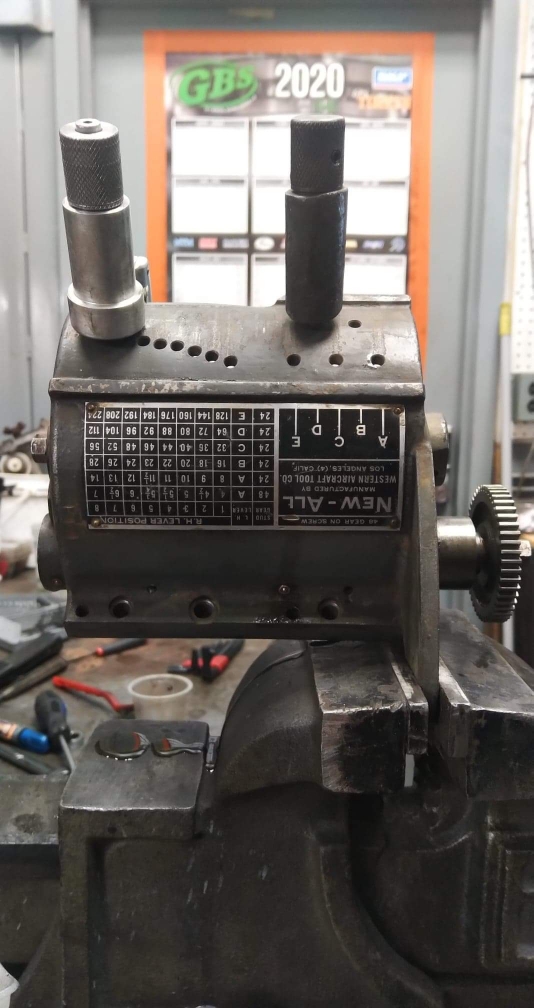

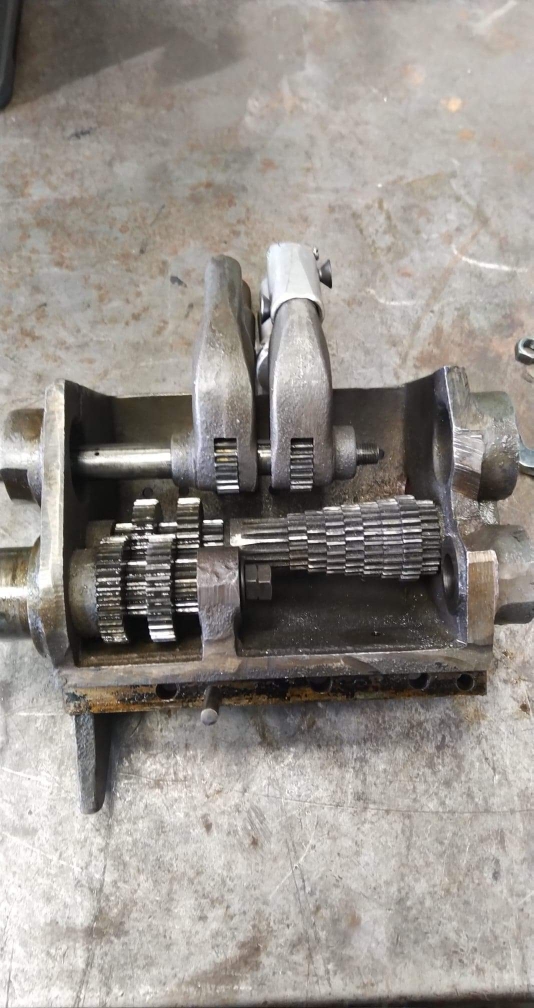

I would like to ask your opinion and get suggestions on how to tackle this. I have a "New All" gear box that is in great shape, mounted on my South Bend lathe. Before I purchased this machine, one feed arm was replaced with a a make shift type arm that simply is annoying to work with.

First and foremost option would be to find a used part, I have had notifications turned on for this on all the big sites, Ebay Kijiji and Craigs, with no avail. I am sure its really rare. Buying a complete feed gearbox is an option, but what I find is old junk at a huge price with an unrealistic shipping cost.

So I was looking at getting this part reproduced. Maybe 3D scanning and CNC machined? I have no experience in this or even where to look for this service, and maybe even harder to find a shop that would do me a one off. Why do I get the feeling this would cost more then I paid for the lathe, I don't mind paying a couple hundred just not a thousand. I find used gearboxes for around $200-$300 USD.

Does anyone have any ideas? Know of a place that has 3D equipment? Should I just try a better repair?

Thanks in advance

Sent from my SM-T590 using Tapatalk

I would like to ask your opinion and get suggestions on how to tackle this. I have a "New All" gear box that is in great shape, mounted on my South Bend lathe. Before I purchased this machine, one feed arm was replaced with a a make shift type arm that simply is annoying to work with.

First and foremost option would be to find a used part, I have had notifications turned on for this on all the big sites, Ebay Kijiji and Craigs, with no avail. I am sure its really rare. Buying a complete feed gearbox is an option, but what I find is old junk at a huge price with an unrealistic shipping cost.

So I was looking at getting this part reproduced. Maybe 3D scanning and CNC machined? I have no experience in this or even where to look for this service, and maybe even harder to find a shop that would do me a one off. Why do I get the feeling this would cost more then I paid for the lathe, I don't mind paying a couple hundred just not a thousand. I find used gearboxes for around $200-$300 USD.

Does anyone have any ideas? Know of a place that has 3D equipment? Should I just try a better repair?

Thanks in advance

Sent from my SM-T590 using Tapatalk