Inspired by the recent posts about multifix, I would like to find more holders for my Rapid Original toolpost. Similar ones are made under different names, but seem to follow the same dimensions. I am looking for size A. The various names I have come across are (Indexa,Dixon,Dickson,Boni Suisse,Feldbach,rapid,bison,Mecanizados and algra)

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rapid Original holders

- Thread starter Ian Moss

- Start date

http://www.gfbgroup.it/rapid-original-eng

@Ian Moss That looks similar to what This Old Tony has on his Colchester.

@Ian Moss That looks similar to what This Old Tony has on his Colchester.

Chipper5783

Super User

I had a Rapid Original "A" on my little lathe (no tool holders). There are several brands (see above) that are similar - but they are not as interchangeable as the Aloris style. I could not get confirmation of fit, and true RO holders are expensive. That is what lead me to the multifix style (the whole set was cheaper than 3 RO holders)

Chipper5783

Super User

The RO was a good looking tool post. One nice feature is that the RO does not add much height, so it will accept 3/4" tools (for a small lathe - 11" swing). When I switched to the "E" multifix I had to skim the bottom of the multifix holders to get the 3/4" tool tip down to center height (made in China holders, but nicely made and very tough material - how to skim the holder and chamfer the spline took some thinking).

Chipper5783

Super User

Interesting, he is changing to a multifix.

Hey John @johnnielsen don't you have these rapid types on your big lathe? I think you made some too?

That is the style I use on my VDF. I had a whole bunch of tool holders so I made a Tool post block to match.Hey John @johnnielsen don't you have these rapid types on your big lathe? I think you made some too?

VDF is a partnership of three or four lathe manufacturers in Germany. Mine was built by Boehringer Goppingen of that partnership.

It is a 19" swing tool room quality lathe with hardened ways, 24 spindle speeds (11-2240), metric, imperial, modulus and diametral threading capabilities. Mine has a six station turret instead of a standard tail stock. It has a separate transmission in the turret which provides about 16 feed rates. The turret moves about 16 inches in auto feed. The attached picture shows it loaded with chips and stuff stacked on and under it. It is a little cleaner now.

It is a 19" swing tool room quality lathe with hardened ways, 24 spindle speeds (11-2240), metric, imperial, modulus and diametral threading capabilities. Mine has a six station turret instead of a standard tail stock. It has a separate transmission in the turret which provides about 16 feed rates. The turret moves about 16 inches in auto feed. The attached picture shows it loaded with chips and stuff stacked on and under it. It is a little cleaner now.

Attachments

riginal "A" on my little lathe (no tool holders). There are several brands (see above) that are similar - but th

The Typo A size from the Italian copy do fit the Dickson tool posts (of the right size of course)

I can see someone moving to the multifix holder as they have the advantage of indexing, the Dickson holders do not. Its actually not at all a bad price for Dickson, I watched for awhile before buying privately and $200-400 US seemed the norm for ebay selling prices. If you need/want one, 300 Cdn going to be hard to beat

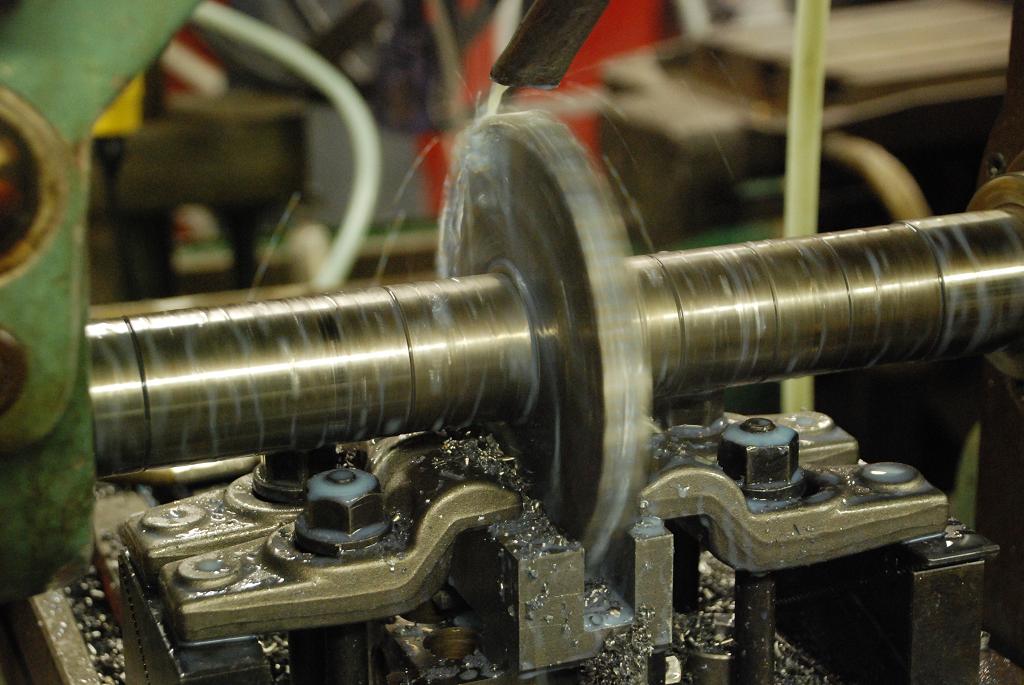

Where the Dickson shines over the multifix is the ease of making the tool holders.....I like lots of tool holders and don't like paying much. some photos of making holders

Edit, didn't mean overwhelm with so many pics...I thought would get links not images

Last edited:

Chipper5783

Super User

I'm impressed. Mill looks like a Victoria (Elliot) for which one can get a vertical head (no quill, but very robust).

Tom O

Ultra Member

Doubleboost got one in the mail for giveaway made by Cronos if anyone wants to try and snag it.

https://www.chronos.ltd.uk/product-category/lathe-quick-change-toolposts/

https://www.chronos.ltd.uk/product-category/lathe-quick-change-toolposts/

Last edited:

I'm impressed. Mill looks like a Victoria (Elliot) for which one can get a vertical head (no quill, but very robust).

Good eye! and thanks. I've got the vertical head and gear but have never mounted it. I have an XLO for vertical work, and its bloody heavy. The vertical gets used 80% of the time, but the horizontal removes 80% of the metal. The vertical head would be a beast with a fly cutter. I have used a 4" flycutter horizontally to face some large blocks, it just peels material off.

How does one make a T slot on a horizontal mill?

I did it in the vertical mill as its easier , or at least more visible, and didn't require the horizontal's umph. To do it in the horizontal, just rotate everything 90 degrees. Workpiece clamped to the table on its side and the cutter held in a collet or tool holder in the spindle

Last edited: