a smile

Lifelong hobby - cold iron

Process of transforming wire cutting machine tools

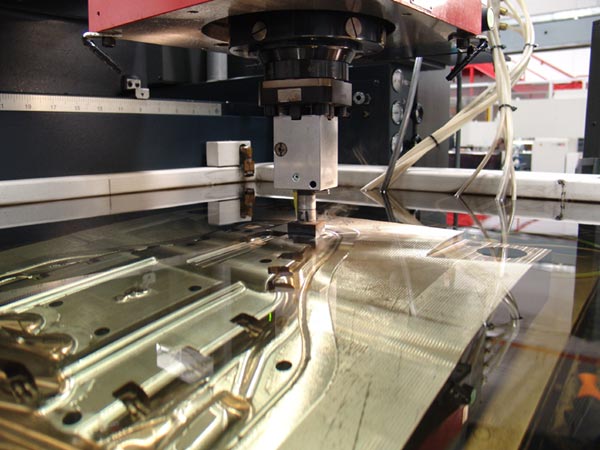

In August 2022, I bought a second-hand wire-cutting machine tool, which has been out of the factory for a long time and is very dirty and old. The operating system X8 has been replaced (paid to be replaced), but many components have been aging due to the age, so there are frequent failures. I haven't operated it for about 3 months, but I'm going to fix it because I have some parts to use it.

This is the current state. I'll record the process as I go along.

There are just a few idle PLC in hand (Mitsubishi FX series), after the increase of PLC can simplify its control circuit, and convenient to improve logic later!

I wrote a piece of basic logic that needs to be refined under these simple frameworks(2022.12)

In August 2022, I bought a second-hand wire-cutting machine tool, which has been out of the factory for a long time and is very dirty and old. The operating system X8 has been replaced (paid to be replaced), but many components have been aging due to the age, so there are frequent failures. I haven't operated it for about 3 months, but I'm going to fix it because I have some parts to use it.

This is the current state. I'll record the process as I go along.

There are just a few idle PLC in hand (Mitsubishi FX series), after the increase of PLC can simplify its control circuit, and convenient to improve logic later!

I wrote a piece of basic logic that needs to be refined under these simple frameworks(2022.12)