Dan Dubeau

Ultra Member

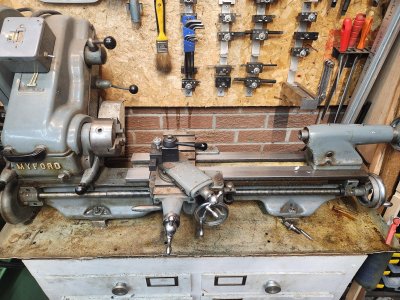

Weather was great, but conditions were too crappy for skiing this weekend, so I did a bunch more cleanup in the shop, and decided to mess it all up again by machining a toolpost for my shaper I've been meaning to get around to for a while.....

This is the look I'm going for here. Sized to take a 5/8"x2" tool shank. It's tough to find info on shaper tooling, but I think most Armstrong styles tool holders for a machine of this size would be around 5/8"x1.5? I added the extra 1/2" and made it 2" just because. I don't think more space is going to hurt anything here, and seeing as how I'll most likely be making all my own tooling for it too, I can make my holders a bit bigger.

http://www.lathes.co.uk/prema-shapers/page3.html

Clean chip pan? It's been a while.....

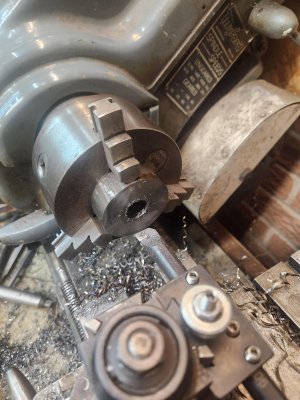

Won't last long once I tear into this 2" chunk of 4140

Import CCMT doing a pretty good job filling that chip pan again.

Saved some chips for a canister damascus at a later date. Ended up with a full jar of fusilli by the end.

Finished op1

Drilled and tapped the end for 1/2"UNC. Small Monkey (F) wrench for turning and a tail center kept me straight. A spring center has been added to my list....

Then I cut off the stub, (made dinner, ate dinner, realized my phone was dead so didn't get pictures of this part....) faced the end, and then and machined the stub into the spacer ring? (not exactly sure what this piece is called. Collar? Base?)

Then I tried it all out for fitment on the clapper. Very nice snug sliding fit for the post. <0.001"

Just a little bit slightly looser fit for the ring. ~0.001-0.0015"

This is where I'm at tonight. Still need to make the screw, and will try and get the slot cut this week. In all honesty it'll probably be next weekend before I get back to it again. My goal here is to not cheat and take it to work. Even though I so badly want to crank out that screw on the Nakamura CNC, or even the Hardinge

![biggrin.png]() . I want to make it all 100% in my own shop with my own machines as part of my past year long big push to sever my reliance on the work shop, and bring my home shop up to where it needs to be to do the projects I want to do. Slowly but surely I'm getting there.

. I want to make it all 100% in my own shop with my own machines as part of my past year long big push to sever my reliance on the work shop, and bring my home shop up to where it needs to be to do the projects I want to do. Slowly but surely I'm getting there.

This is the look I'm going for here. Sized to take a 5/8"x2" tool shank. It's tough to find info on shaper tooling, but I think most Armstrong styles tool holders for a machine of this size would be around 5/8"x1.5? I added the extra 1/2" and made it 2" just because. I don't think more space is going to hurt anything here, and seeing as how I'll most likely be making all my own tooling for it too, I can make my holders a bit bigger.

http://www.lathes.co.uk/prema-shapers/page3.html

Clean chip pan? It's been a while.....

Won't last long once I tear into this 2" chunk of 4140

Import CCMT doing a pretty good job filling that chip pan again.

Saved some chips for a canister damascus at a later date. Ended up with a full jar of fusilli by the end.

Finished op1

Drilled and tapped the end for 1/2"UNC. Small Monkey (F) wrench for turning and a tail center kept me straight. A spring center has been added to my list....

Then I cut off the stub, (made dinner, ate dinner, realized my phone was dead so didn't get pictures of this part....) faced the end, and then and machined the stub into the spacer ring? (not exactly sure what this piece is called. Collar? Base?)

Then I tried it all out for fitment on the clapper. Very nice snug sliding fit for the post. <0.001"

Just a little bit slightly looser fit for the ring. ~0.001-0.0015"

This is where I'm at tonight. Still need to make the screw, and will try and get the slot cut this week. In all honesty it'll probably be next weekend before I get back to it again. My goal here is to not cheat and take it to work. Even though I so badly want to crank out that screw on the Nakamura CNC, or even the Hardinge