Doggggboy

Ultra Member

The x axis powerfeed died on the mill.

Precision Mathews does not handle any parts for it.

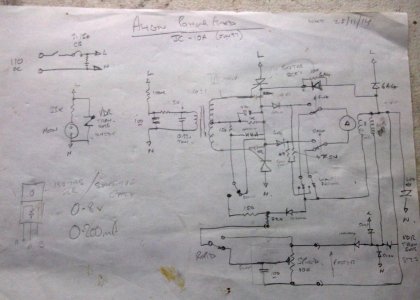

I've ordered a new board from ebay but the old board still kinda works, just no speed control, it's all or nothing. You can see the fried parts on the board below but I can't read the badly burnt one in the middle. Any guesses?

The board is an AL-510S 120v.

![ABLVV845oQbKhjp-4eX6uC-n3N-fn404VHLwEpN8dzjYE0fdlgDdtmrvG9fCUza2gLboIbsVyvg0ek_hmIkSUJppsE8cyRZcK-0i4o7GvlBIGaHaDhFBEUsBd9D5EG1pbXyp-2ba54tb78qZKL3k5zssM-n_jelA7F_hYF2Ys8I8vxsZm6tkuAcvEqNlaB0fYVvbT4Jin1McyBDZ2KFm6yR40sIJ-Zm6ihA4cbdfB5IqocyOOTnxLhzn1l7ves9o1JZ5vNfoCaUQUf6kufzU4dp90Ws7usf2XlX2KqRtqpJlXfwzphwHIjlRBjjY6GLdIB-8GipcsAWXkzaPs-4KRW7nsXxcwcGTmcGoDCdB0XBzQT9-nFvYdqtA-PisqkzETFqM-71SF524gAKOx_CRaQgG34HAjWMs0fwL9Wtf3yZjR6q9FjVF6DUU8L1dfGRh2IRBeHN8jYVyHv5bmKUVpg1rDdh1JwhVTAEVAtRxE8F-QVis4ZLevhuX57byutF29fOi8Ow4EB1G8j63L_qL7vPXhkuHQrT3InAxVYBL7Pk9Jmcva2El8hTD91Ui4suHRU-3nbpX5NJzyshqdBFHRwcfpu_la1kkJnc2O7Lno-950VWINaaBChJBg1szMTFaxyHXmREoDkV-CFm2SjRVZTmFMt1Mimj08tN55iupQt0H08ucMVld897vOk5ixbs4prraz_zvhzMkhWmui1bmG1I41N4ou6BGNEcNrzb-BmJw8DDeUPfYxrqU_DC2oDtsRt55BbEkdFSYcwFg0AOAcFZVNnk_FNv2xSOXi7MbXsj2iSiDQ3K5xzI6oCiMsKuLVvfTqXuXPsE5oqjDV4_1VNQKFm_7Ry_QfzBIm30hs3EgPYomDJn9WFW1fTseyzaU8vppy82AirbPKoK42roj-iY6PwtgcCI=w803-h602-s-no-gm]()

Precision Mathews does not handle any parts for it.

I've ordered a new board from ebay but the old board still kinda works, just no speed control, it's all or nothing. You can see the fried parts on the board below but I can't read the badly burnt one in the middle. Any guesses?

The board is an AL-510S 120v.