slow-poke

Ultra Member

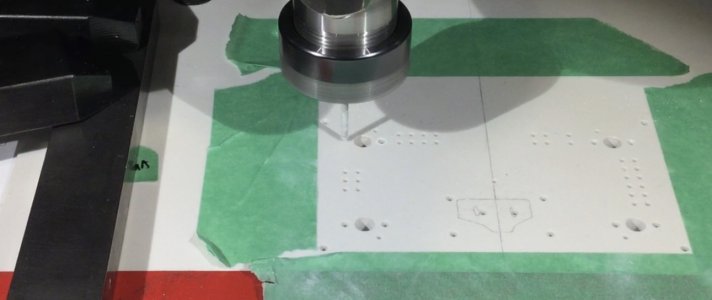

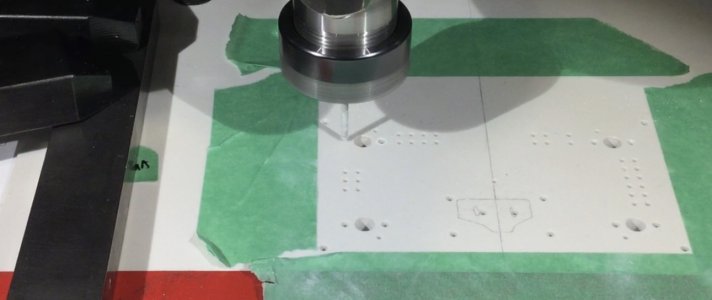

From time to time I need to drill and mill plates that are about 17" x 17" x 1/2". These plates are made of some unknown material that would best be described as a mix of GR4 (PCB fibreglass) and bakelite. Whatever the material is it drills and machines easily with small drill bits and or 1/8" end mills. When milling the residue is more powder like than the stringy swarf that occurs when milling GR4.

Accuracy requirements are say +/- 0.002" for drilling and +/- 0.005 for milling.

Presently I'm machining these on my mill because that's what I have available and in most cases the actual drill/mill area is a fair bit smaller than the actual plate typically 5" x 12" or smaller and my mill accommodates that.

I'm now looking for a inexpensive hobby or very light industrial class CNC router or router kit that will better accommodate these 17" x 17" plates and allow me to mill drill anywhere in the center say 16" area. The closer to plug and play the better, Some assembly is fine, but expectation is that it works out of the box without having to fix it all the time.

Usage will be about once per month drilling perhaps 100 holes and milling 10 cutouts say 1" x 1"

The drilling / milling specification provided typically comes in .txt or spreadsheet form and I simply use the text replace feature in an editor to convert to g code.

Thanks in advance and looking forward to your suggestions.

suggestions.

Accuracy requirements are say +/- 0.002" for drilling and +/- 0.005 for milling.

Presently I'm machining these on my mill because that's what I have available and in most cases the actual drill/mill area is a fair bit smaller than the actual plate typically 5" x 12" or smaller and my mill accommodates that.

I'm now looking for a inexpensive hobby or very light industrial class CNC router or router kit that will better accommodate these 17" x 17" plates and allow me to mill drill anywhere in the center say 16" area. The closer to plug and play the better, Some assembly is fine, but expectation is that it works out of the box without having to fix it all the time.

Usage will be about once per month drilling perhaps 100 holes and milling 10 cutouts say 1" x 1"

The drilling / milling specification provided typically comes in .txt or spreadsheet form and I simply use the text replace feature in an editor to convert to g code.

Thanks in advance and looking forward to your

suggestions.

suggestions.