Anyone in here have/know someone with a milling machine in the Ottawa area that can give me a hand?

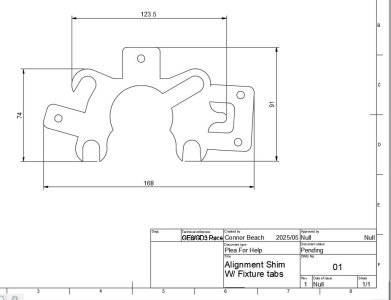

Looking to have a flat taper cut in these alignment shims. Varying orientations/tapers for a full set. Not precision work. Not particularly time sensitive.

Will come laser cut as you see drawn in ~3mm mild steel.

Work holding via a fixture plate with bolts (maybe super glue on the edges if needed). I can dimension it for T-slot table/ huge vise, or whatever you want really. Work holding easily changed.

If interested please reach out! Thanks

Looking to have a flat taper cut in these alignment shims. Varying orientations/tapers for a full set. Not precision work. Not particularly time sensitive.

Will come laser cut as you see drawn in ~3mm mild steel.

Work holding via a fixture plate with bolts (maybe super glue on the edges if needed). I can dimension it for T-slot table/ huge vise, or whatever you want really. Work holding easily changed.

If interested please reach out! Thanks

Attachments

Last edited: