@skippyelwell

Further to my comments above, I went out to the shop this morning and had a look at what I use regularly and prepared the following lists for you. This is just my list which is based somewhat on what I do and what I recommend. Others will disagree and that's ok. There is always more than one way to skin a moose.

Basic Tools and Accessories that normally come with the lathe:

- 3 jaw scrolling chuck

- 4 jaw independent chuck

- tailstock

- toolholder

Optional (not necessarily required) Accessories that often come with the lathe but can be made if not - some skill is required. For me, these are selling features that might influence the price I'm willing to pay. For small work close to the chuck, they are not needed.

- steady rest

- follow rest

Accessories that should be purchased if not already with the lathe:

- 1/2" drill chuck to fit your tailstock

- Lathe Files

- 1 inch Plunge Style Indicator 0.001 with mag base and tool holder base

- Dial Test Indicator 0.0005 or 0.0001 with mag base and tool holder base

- Good quality 1 and 2" outside and inside micrometers

- 6 inch calipers - vernier, dial, or digital

- Good way oil

- Lathe Center Height Standard (make this for your lathe - lots of examples on the forum)

- Lathe chuck steps. You can use parallels for this till you buy or make something better

- Rear Spider for through spindle stock

- Small parts chuck (only needed for bigger lathes)

- Dead Centers and drive dogs

- Assortment of HSS tool bits and shims

- Assorted sizes of HSS Boring bars

- Parting blades & holders

- Center Drill Set

- Machinery's Handbook

- Conversion Charts

- Feeds N Speeds Charts

- Tap & Drill Calculator or Chart

- Good LED light

- Cutting fluids for various metals

- brushes, brush dip can, and dripper

- Headstock oil

- Other oils as required

- Tools and Allen wrenches to fit every adjustment on your lathe

- Plywood way protector or better yet custom Chuck Bed Supports

For threading with taps and dies you should have:

- Threading die holders

- Threading tap follower

For single point threading you should have:

- Threading gauges

- 60 deg gauge

- hss threading tools

Other nice to have equipment

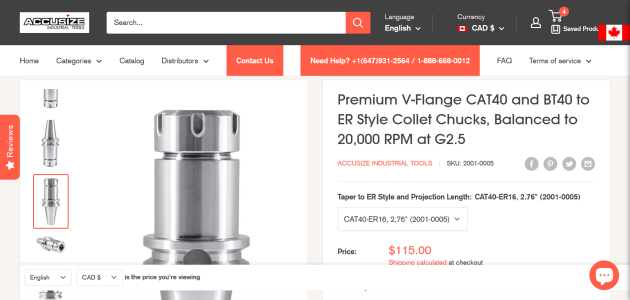

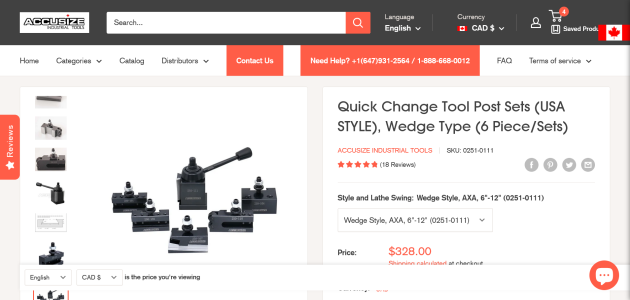

- A nice wedge or piston style Aloris clone tool post and tool holders.

- 5C Collet chuck and collets

Cruise this forum for how-to threads and other interesting tools.

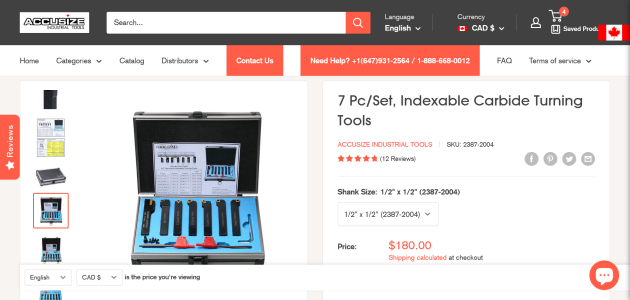

I highly recommend starting with HSS tooling and learning how to grind tool bits first. This will teach you things you need to know. You can get Carbide Insert Tooling when and if you are ready. Lots of members only use HSS.

Screenshot 2024-12-12 at 09-37-48 7 Pc Lathe Toolset Indexable Carbide Turning Tools.png581.2 KB · Views: 18

Screenshot 2024-12-12 at 09-37-48 7 Pc Lathe Toolset Indexable Carbide Turning Tools.png581.2 KB · Views: 18 Screenshot 2024-12-12 at 09-37-15 Quick Change Tool Post Sets (USA STYLE) Wedge Type (6 Piece_...png342.4 KB · Views: 19

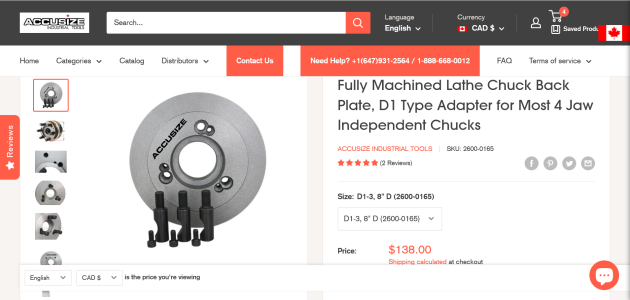

Screenshot 2024-12-12 at 09-37-15 Quick Change Tool Post Sets (USA STYLE) Wedge Type (6 Piece_...png342.4 KB · Views: 19 Screenshot 2024-12-12 at 09-36-32 Fully Machined Lathe Chuck Back Plate D1 Type Adapter for Mo...png528.8 KB · Views: 20

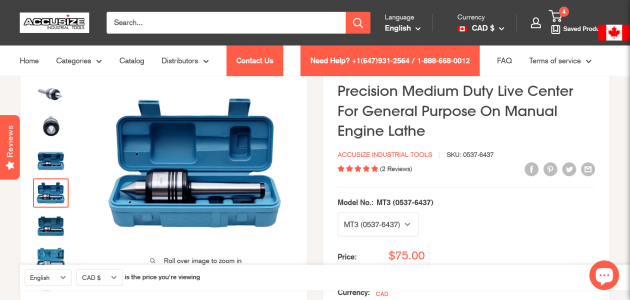

Screenshot 2024-12-12 at 09-36-32 Fully Machined Lathe Chuck Back Plate D1 Type Adapter for Mo...png528.8 KB · Views: 20 Screenshot 2024-12-12 at 09-35-46 Precision Medium Duty Live Center For General Purpose On Man...png518.2 KB · Views: 17

Screenshot 2024-12-12 at 09-35-46 Precision Medium Duty Live Center For General Purpose On Man...png518.2 KB · Views: 17