Ya know...this 1" HSS endmill has been the bane of my existence! Almost everytime I've used it over the last 20 years it has caused me misery, except when using it to true up walnut. My severed tendon on my left hand was when using this; endmill pull outs, and poor finishes. Why I still have it is a mystery. Truth be told, its mostly my fault for not ensuring a rigid enough set up.

Well last night, I just wanted to side mill a steel surface. The tooth grabbed and pulled the material in, with a huge clunk everything stopped. The VFD turned off the motor due to overcurrent. (Which is a good thing.) Well then I decided to measure if still in tram.

The mill vise was twisted, nod, and cant of the head had moved too. And not by a couple thou', more like 20-40 thou'. #$%^&#$#!!

So trammed the head and vise. I hadn't checked it in a while, so it's probably a good thing.

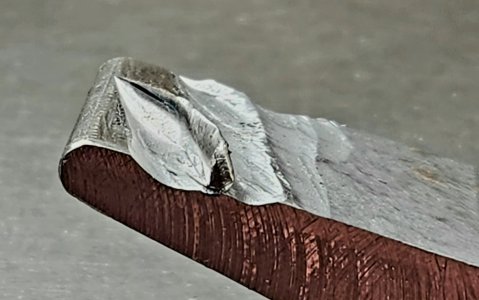

Though, the inside of the collet and the shaft of the endmill are badly galled. And that's a $50.00 Techniks 3/4" collet!

Oh, well...live and learn....though as I get older, I can't remember what I learn anymore.

Well last night, I just wanted to side mill a steel surface. The tooth grabbed and pulled the material in, with a huge clunk everything stopped. The VFD turned off the motor due to overcurrent. (Which is a good thing.) Well then I decided to measure if still in tram.

The mill vise was twisted, nod, and cant of the head had moved too. And not by a couple thou', more like 20-40 thou'. #$%^&#$#!!

So trammed the head and vise. I hadn't checked it in a while, so it's probably a good thing.

Though, the inside of the collet and the shaft of the endmill are badly galled. And that's a $50.00 Techniks 3/4" collet!

Oh, well...live and learn....though as I get older, I can't remember what I learn anymore.