Never have I ever............ turned a piece of steel and gotten a mirror like finish like I get from turning aluminum with a new indexable insert tool.....until today!

I was getting set up to make a doodad to mount my mill DRO display and deciding which of my HSS, brazed carbide or insert tools to use on a piece of cold rolled bar. I've never been satisfied, often I'll get a decent finish, sometimes it turns out pretty good usually with HSS but I've never been truly happy with the result. It's usually the typical gummy steel part that's decent and functional.

On a whim tonight I took @Dabbler 's advice and dressed the flanks and nose of an indexable carbide insert with a diamond EZE Lap and was blown away with the result. Like night and day even after I've stepped up my HSS grinding & polishing.

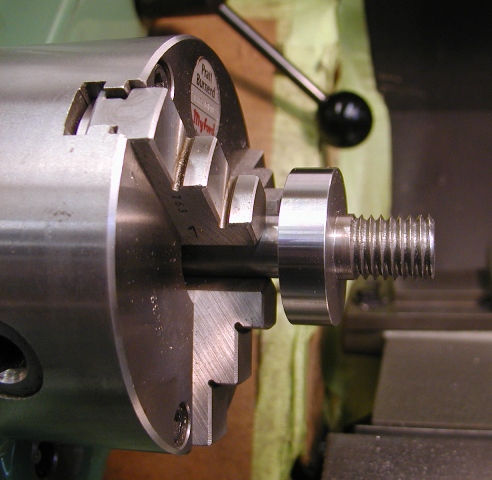

OK, I'm a detail guy so: .030 DOC, .002 feed with a SOWA DCMT21.51-F2P insert, 1-1/2" cold rolled bar running 720 RPM so ~280 SFPM. The finish was actually better for the first cuts & not quite as good as the diameter decreased. The chips were coming off between brown and bright blue and HOT on the hand waiting to disengage the carriage feed (ouch!). It was coming off in chips too, not ribbons.

Oh, and the DRO saved a lot of jigging around with carriage stop/dial indicators and stopping to take measurements. I think I'm going to be using the micrometer more and calculator less with the DRO.

Never stop learning.

Anyhow, I just had to share.

D

I was getting set up to make a doodad to mount my mill DRO display and deciding which of my HSS, brazed carbide or insert tools to use on a piece of cold rolled bar. I've never been satisfied, often I'll get a decent finish, sometimes it turns out pretty good usually with HSS but I've never been truly happy with the result. It's usually the typical gummy steel part that's decent and functional.

On a whim tonight I took @Dabbler 's advice and dressed the flanks and nose of an indexable carbide insert with a diamond EZE Lap and was blown away with the result. Like night and day even after I've stepped up my HSS grinding & polishing.

OK, I'm a detail guy so: .030 DOC, .002 feed with a SOWA DCMT21.51-F2P insert, 1-1/2" cold rolled bar running 720 RPM so ~280 SFPM. The finish was actually better for the first cuts & not quite as good as the diameter decreased. The chips were coming off between brown and bright blue and HOT on the hand waiting to disengage the carriage feed (ouch!). It was coming off in chips too, not ribbons.

Oh, and the DRO saved a lot of jigging around with carriage stop/dial indicators and stopping to take measurements. I think I'm going to be using the micrometer more and calculator less with the DRO.

Never stop learning.

Anyhow, I just had to share.

D