As an extension of the recent post by @van123d

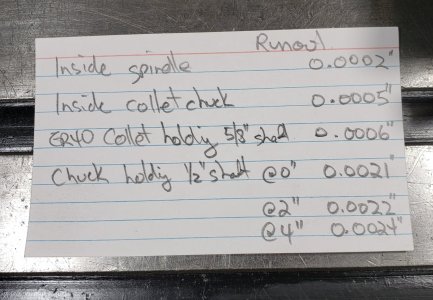

on drill chuck recommendations, I decided to measure a few things. I have an Albrecht 1/2" drill chuck with and integral 5/8" straight shank. I purchased it 36 years ago to drill holes using my Ex-Cell-O 602 milling machine. I've used it to drill holes almost every day since I bought it. If I only drilled one hole a day, that would be 13,000 holes. I decided to measure the run-out of the chuck. But the drill chuck is held in the mill with a NMTB-40 ER40 collet chuck. So I measured the run-out inside the mill spindle, inside the collet chuck cavity, the collet gripping a 5/8" shaft, and then the Albrecht chuck gripping a 1/2" shaft ( at close to the drill chuck jaws; 2" further down, and then 4" away). Measurements were taken with a Mitutoyo tenths DTI. See the results below. Not too bad for an old, well used drill chuck.

on drill chuck recommendations, I decided to measure a few things. I have an Albrecht 1/2" drill chuck with and integral 5/8" straight shank. I purchased it 36 years ago to drill holes using my Ex-Cell-O 602 milling machine. I've used it to drill holes almost every day since I bought it. If I only drilled one hole a day, that would be 13,000 holes. I decided to measure the run-out of the chuck. But the drill chuck is held in the mill with a NMTB-40 ER40 collet chuck. So I measured the run-out inside the mill spindle, inside the collet chuck cavity, the collet gripping a 5/8" shaft, and then the Albrecht chuck gripping a 1/2" shaft ( at close to the drill chuck jaws; 2" further down, and then 4" away). Measurements were taken with a Mitutoyo tenths DTI. See the results below. Not too bad for an old, well used drill chuck.