Chris Cramer

Super User

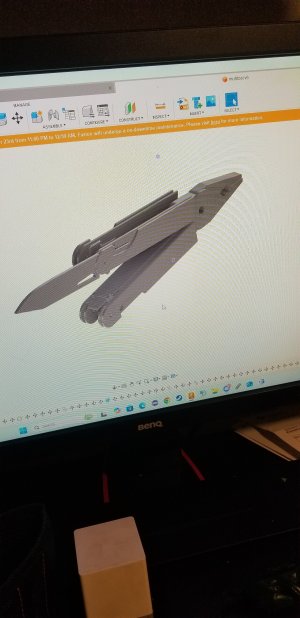

I've completed my model on fusion for my first multitool I want to attempt to assemble. I studied one of my old multitools for a good idea on how the device works to hold and lock all the different tools into the frame. It's not too complicated, mostly just a series of springs that are part of the frame which is usually bent into shape. I tried shaping some 16 gauge SS that I cut with my plasma table by bending every joint but I don't think that would look very straight without the correct rolling machines. Instead I re designed it to come together as separate cut parts that I could tig weld together instead of keeping the whole frame in one piece.

The tool's inside I would just fabricate like I do most of my knife blades.

The tool's inside I would just fabricate like I do most of my knife blades.