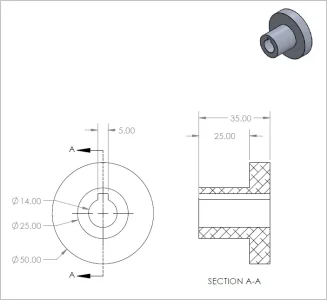

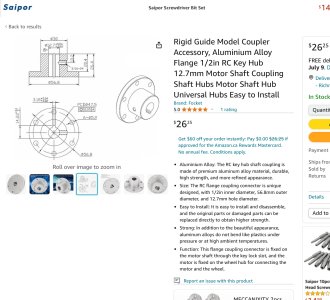

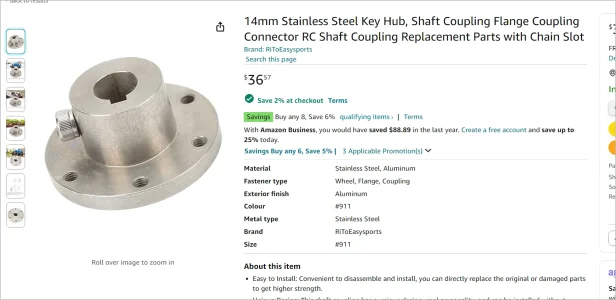

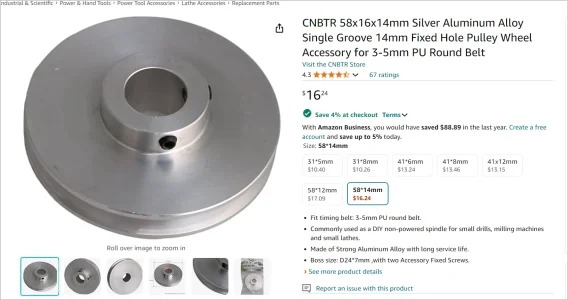

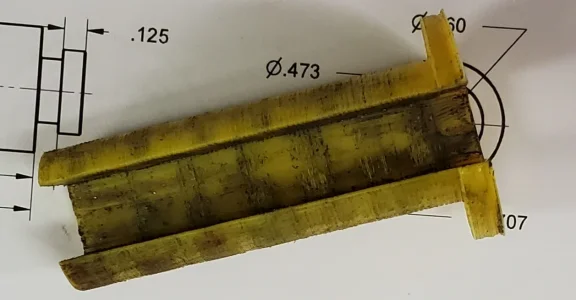

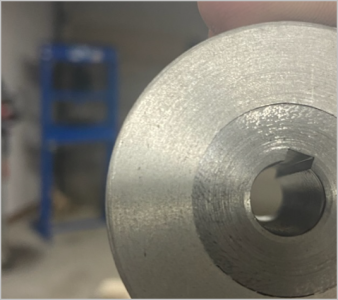

I'm trying to match a hub to a motor shaft, ideally by using something that exists so I further machine it. Other than the 14mm shaft bore & 5mm keyway slot, the remaining dimensions are just approximate. Really the only thing I'm not set up for is the keyway slotting. Maybe I'm not using the right term. I see al kinds of couplings but nothing like this. Any ideas?