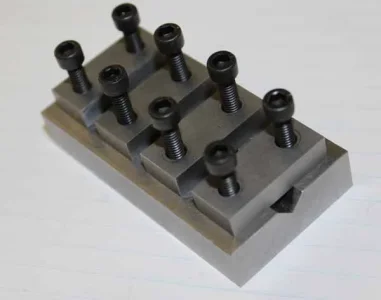

Nothing special - a rainy day project using up some scrap HRS. I needed a fixture with a few features that made using regular V-blocks less suitable. I need to hold round stock & machine different areas down the length, hence the series of hold-down clamp positions so I can keep the stock locked down & change clamps. I find those U-clamps on standard V blocks either in the way of the quill, or not holding securely during machining. I also need to orientate this jig in the mill vise at a specific angle top view (not shown but plan on using some matching front & rear angle blocks).

It turned out not bad I guess. A surface grinder would come in handy right about now 🙂 I'm going to blacken it just for rust protection. The V-groove was a learning experience. I set the rectangular blank up in a standard V block & used an end mill distanced off an edge for centering. As you can see, the side mill side finished nicer than the bottom mill side. So next time I should either flip it to do both sides the same? I might actually make me a series of say 3 blocks with different V groove depths so I'm equipped to hold any progressive diameter like 2mm 5mm 10mm etc. Anyway, hopefully one of those homebrew tools you cant find in catalogs.

It turned out not bad I guess. A surface grinder would come in handy right about now 🙂 I'm going to blacken it just for rust protection. The V-groove was a learning experience. I set the rectangular blank up in a standard V block & used an end mill distanced off an edge for centering. As you can see, the side mill side finished nicer than the bottom mill side. So next time I should either flip it to do both sides the same? I might actually make me a series of say 3 blocks with different V groove depths so I'm equipped to hold any progressive diameter like 2mm 5mm 10mm etc. Anyway, hopefully one of those homebrew tools you cant find in catalogs.