-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MINE!

- Thread starter calgaryguy

- Start date

calgaryguy

Chris

calgaryguy

Chris

Getting it off the truck was surprisingly easy by myself. Manual says to use the casting cross-boss right where you see the sling and to advance the carriage all the way to the end. It was 'mostly' balanced this way, probably would have been a perfect balance with the 3 jaw removed.

Way to go. That makes three of us in Calgary with a 9" Utilathe now. @StefanMFrey has one as well.

Brent H

Ultra Member

Bravo @calgaryguy bravo!!! You should have lots of fun !! Congratulations on the new family member!!

calgaryguy

Chris

calgaryguy

Chris

Next steps will be a thorough cleaning and sourcing a small VFD to run it off of

cross-slide handle backlash is about .011 and the compound slide backlash is about .016 measured at the handle/dial. carriage moves freely all the way to both ends withoutb feeling loose in the middle. There is a small amount of visible wear (the acme thread is a little bit thinner for about 2-3 rotations) on the feed screw right where you would expect alot of 6" stubs in the chuck being worked on otherwise the feed screw is in great shape.

cross slide moves freely all the way forward and back, with a little more 'looseness' felt in the handle in the middle of its travel. compound feels smooth all the way thru.

cross-slide handle backlash is about .011 and the compound slide backlash is about .016 measured at the handle/dial. carriage moves freely all the way to both ends withoutb feeling loose in the middle. There is a small amount of visible wear (the acme thread is a little bit thinner for about 2-3 rotations) on the feed screw right where you would expect alot of 6" stubs in the chuck being worked on otherwise the feed screw is in great shape.

cross slide moves freely all the way forward and back, with a little more 'looseness' felt in the handle in the middle of its travel. compound feels smooth all the way thru.

Nice score. I wonder if I took some machining classes on one of its brothers or sisters. Think of the history. How many keys got launched from that chuck LOL

Did you get it from SAIT or you mean from someone else who got it from SAIT?

Its been a while since I poked my head into one of their classes but I seem to recall bigger / metric machines. Who knows maybe those are long gone by now too.

Did you get it from SAIT or you mean from someone else who got it from SAIT?

Its been a while since I poked my head into one of their classes but I seem to recall bigger / metric machines. Who knows maybe those are long gone by now too.

calgaryguy

Chris

When @kevin.decelles and I took the basic machining course probably 5 years back the big shop on the second floor had a bunch of those SM machines. They looked good to me. In the class we were using bigger blue machines imported from Asia. Don’t recall the size or brand. Bigger than my 14x40.Nice score. I wonder if I took some machining classes on one of its brothers or sisters. Think of the history. How many keys got launched from that chuck LOL

Did you get it from SAIT or you mean from someone else who got it from SAIT?

Its been a while since I poked my head into one of their classes but I seem to recall bigger / metric machines. Who knows maybe those are long gone by now too.

calgaryguy

Chris

Other than the ways and crossfeed being a little beat, it *seems* (to my untrained eye) to be in overall decent shape. I'm going to spend some time getting to know this machine and its tolerances before I do any serious work with it.

EDIT: I should mention that I need to get caught up on my woodworking machine projects and get them moved along to their new owners. I'll give $5 to anyone who can accurately count the number of Rockwell or Delta Unisaw Cabinet tablesaws (complete or in various stages of rebuild) in the pics above. LOL. I also promised my lovely missus that before I buy anything else 'new to me' she can have a 'new' (new to her) upright piano to replace the 1950's one she plays on now (badly out of tune, needs complete restring, etc). She has her passions and I have mine. Fair deal.

EDIT: I should mention that I need to get caught up on my woodworking machine projects and get them moved along to their new owners. I'll give $5 to anyone who can accurately count the number of Rockwell or Delta Unisaw Cabinet tablesaws (complete or in various stages of rebuild) in the pics above. LOL. I also promised my lovely missus that before I buy anything else 'new to me' she can have a 'new' (new to her) upright piano to replace the 1950's one she plays on now (badly out of tune, needs complete restring, etc). She has her passions and I have mine. Fair deal.

calgaryguy

Chris

I hadnt thought about easy rpm changes and not changing the belt... Hmm.

Congrats, it's a great machine and I enjoyed mine immensely. There are quite a few posts and good info on the site about the SM9 and SM lathes in general.

Did you have a chance to hear it running and go thru the gears? The drawings for the follow rest are in the plans section and I'm sure the other two YYC guys will help you out when needed.

Does the chuck come off easily?

I have a few HS gears and a spindle (with bearing) if you need them.

Did you have a chance to hear it running and go thru the gears? The drawings for the follow rest are in the plans section and I'm sure the other two YYC guys will help you out when needed.

Does the chuck come off easily?

I have a few HS gears and a spindle (with bearing) if you need them.

I hadnt thought about easy rpm changes and not changing the belt... Hmm.

Belt changes are trivial on that machine, but ya, a VFD would provide virtually infinite speed control. I have no desire to convert mine to 3 PH.

calgaryguy

Chris

I havent tried getting the chuck off.Congrats, it's a great machine and I enjoyed mine immensely. There are quite a few posts and good info on the site about the SM9 and SM lathes in general.

Did you have a chance to hear it running and go thru the gears? The drawings for the follow rest are in the plans section and I'm sure the other two YYC guys will help you out when needed.

Does the chuck come off easily?

I have a few HS gears and a spindle (with bearing) if you need them.

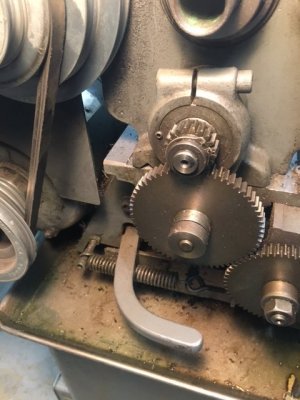

I did hear it running and ran thru a couple of gears. It was 'noisy' but I have no baseline to compare it to. The spindle turns smooth and none of the gears show abnormal wear, chipped or broken teeth.

Did I send you this link yet? http://www.lathes.co.uk/standardmodern/index.html