DPittman

Ultra Member

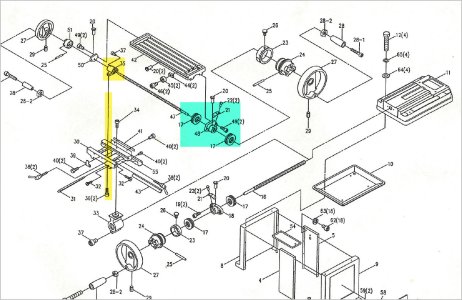

I'm trying to adjust the x axis backlash on my milling machine. There are two adjustment bolts on the leadscrew nut and I have adjusted them up to the point the x axis handwheel turn hard the one direction but it seems to have little effect on the backlash itself. I suspect the problem is with how the nut itself is held in place. I don't know how it is held and I fear having to dismantle a whack to access it. My mill is an Asian 6x26.

The video might help.

https://youtube.com/shorts/ti2CsOgReoc?feature=share

The video might help.

https://youtube.com/shorts/ti2CsOgReoc?feature=share