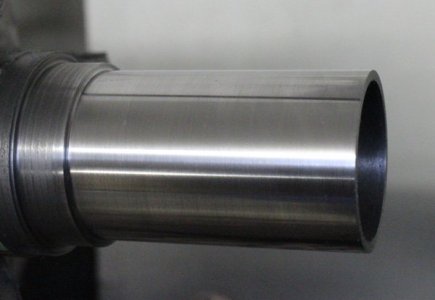

Just curious, when the piston is hard plated like that, what is the matching prescribed liner bore protocol? Is it un-plated alloy or plated with something different?

I'm having trouble visualizing the break in equivalent of the modern race engines - 'hard' tapered liner & 'soft' cylindrical piston that molds itself into the magic barrel shape. But all this is above my pay grade.

I'm having trouble visualizing the break in equivalent of the modern race engines - 'hard' tapered liner & 'soft' cylindrical piston that molds itself into the magic barrel shape. But all this is above my pay grade.