calgaryguy

Chris

Per the title, I need to make, or have made, a plate adapter to go from a NEMA 56C *inch fractional* frame electric motor housing flange to a B5 D71 *metric* flange. I dont think the Craftex lathe I have access to is a) has a chuck capable of spinning a flange this size, and the RF-30 mill I have access to is beat to shit and isnt very precise anymore, nor do I have a good/accurate way to index things like the bolt holes and spacings required

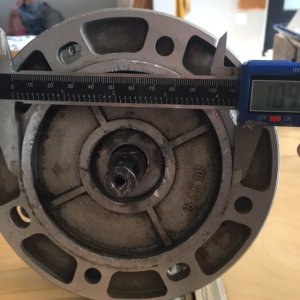

NEMA 56C drawing is attached for reference. Picture of a typical Leeson 56C attached as well.

The *KEY* dimensions from the attached 56C pdf drawing needed for the 56C motor facing side of the proposed adapter plate are the BF and AJ measurements for the mounting bolt hole size and spacings AND critically the AK dimension which would need to be a recess in the motor facing side of the adapter. proper positioning of AK, BF, and AJ will ensure that the shaft stays perfectly centered in the flange.

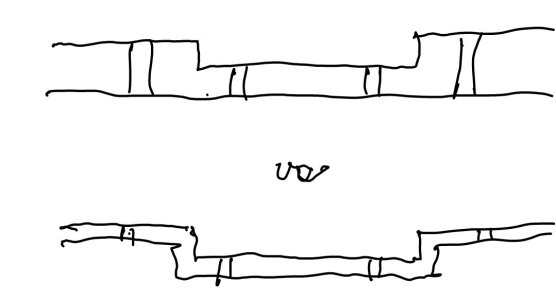

The thickness of the adapter plate is dependant on two key measurements:

1) The ACTUAL shaft length protruding from the motor housing. The attached PDF has that measurement as 2 1/16", but I have seen NEMA 56C motor (princess auto cheapos for eg) advertised with 1 7/8" to 2".

2) The shaft length that must protrude from the face of the B5 Flange side of the adapter needs to be 1.185". This length is critical as there is a gear that gets installed on the shaft that meshes into a gearbox.

The B5 flange side of the adapter needs to meet D71 metric specs. Please see the attached IEC B5 D Flange dimensions PDF. Note again I need a Frame 71 size. Also important to note that IEC Frame 56 and NEMA frame 56 are NOT the same.

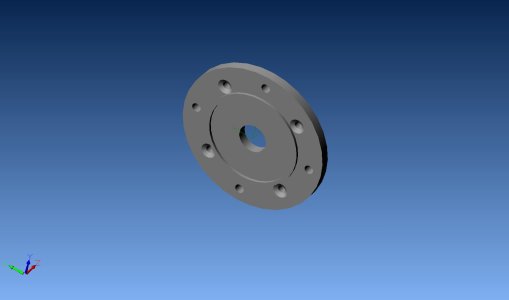

I dont have CAD and my fusion360 skills are non-existent. I did HOWEVER find the a CAD/STEP file for a NEMA frame 56C to IEC B5 *D80* adapter flange at https://grabcad.com/library/56c-frame-to-b5-frame-motor-adaptor . Can this be easily modified to have a D71 face instead of a D80? I've downloaded the .stp file and zipped it and the available redering from grabcad and attached it here for anyone curious.

NEMA 56C drawing is attached for reference. Picture of a typical Leeson 56C attached as well.

The *KEY* dimensions from the attached 56C pdf drawing needed for the 56C motor facing side of the proposed adapter plate are the BF and AJ measurements for the mounting bolt hole size and spacings AND critically the AK dimension which would need to be a recess in the motor facing side of the adapter. proper positioning of AK, BF, and AJ will ensure that the shaft stays perfectly centered in the flange.

The thickness of the adapter plate is dependant on two key measurements:

1) The ACTUAL shaft length protruding from the motor housing. The attached PDF has that measurement as 2 1/16", but I have seen NEMA 56C motor (princess auto cheapos for eg) advertised with 1 7/8" to 2".

2) The shaft length that must protrude from the face of the B5 Flange side of the adapter needs to be 1.185". This length is critical as there is a gear that gets installed on the shaft that meshes into a gearbox.

The B5 flange side of the adapter needs to meet D71 metric specs. Please see the attached IEC B5 D Flange dimensions PDF. Note again I need a Frame 71 size. Also important to note that IEC Frame 56 and NEMA frame 56 are NOT the same.

I dont have CAD and my fusion360 skills are non-existent. I did HOWEVER find the a CAD/STEP file for a NEMA frame 56C to IEC B5 *D80* adapter flange at https://grabcad.com/library/56c-frame-to-b5-frame-motor-adaptor . Can this be easily modified to have a D71 face instead of a D80? I've downloaded the .stp file and zipped it and the available redering from grabcad and attached it here for anyone curious.