My lathe has been short a steady rest for as long as ive owned it, thoughts of building one had crossed my mind for a few years.....Untill @Tom Kitta posted one for sale that could be close enough to make work

After confirming it wouldnt fit, it was off to the bandsaw for some hacking, then to the mill for some flattening, then back to the bandsaw for more hacking and to the mill for more flattening

Side quest, milling a slot in the steady rest finger thing for a better and more positive retention, as well as replacing the m6 bolts with m6 set screws

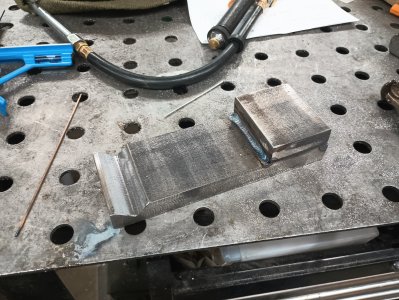

Scavenged a piece of 3/4 plate from the shop to make the new base from, cut, squared the sides, and milled the slot....this setup did cost me an endmill, but it was the only way i could make it work with my equipment, so oh well

Milled the v slot deep enough so that i would be able to use another piece of that same 3/4 in order to drop down to the rear way, welded on, milled to correct height

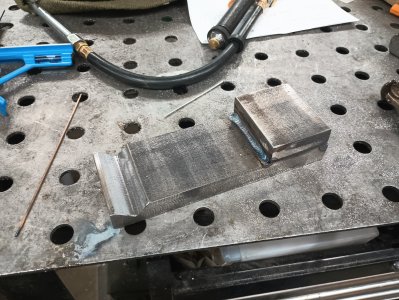

back in situ to tack the rest on with the tig, removed to weld with stick, i had only 2 sticks of nickel rod, so did the root passes and the rest with 7018, i forgot how garbage that stuff runs, blasted, and primed.

next up will be the the plate for the underside of the bed, i dont think there is any need for photos of that

After confirming it wouldnt fit, it was off to the bandsaw for some hacking, then to the mill for some flattening, then back to the bandsaw for more hacking and to the mill for more flattening

Side quest, milling a slot in the steady rest finger thing for a better and more positive retention, as well as replacing the m6 bolts with m6 set screws

Scavenged a piece of 3/4 plate from the shop to make the new base from, cut, squared the sides, and milled the slot....this setup did cost me an endmill, but it was the only way i could make it work with my equipment, so oh well

Milled the v slot deep enough so that i would be able to use another piece of that same 3/4 in order to drop down to the rear way, welded on, milled to correct height

back in situ to tack the rest on with the tig, removed to weld with stick, i had only 2 sticks of nickel rod, so did the root passes and the rest with 7018, i forgot how garbage that stuff runs, blasted, and primed.

next up will be the the plate for the underside of the bed, i dont think there is any need for photos of that