terry_g

Ultra Member

The collet block set I ordered the nut was too big to fit in the bore of my 3 jaw chuck. Making a smaller one was the next project.

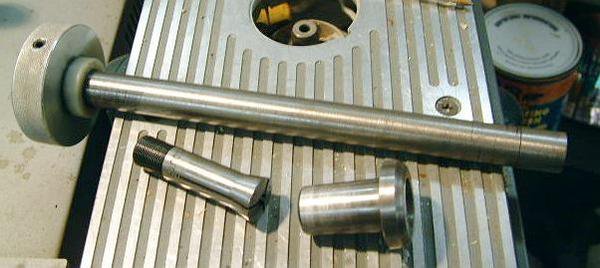

The 5C collets have an odd sized thread 1.238" x 20 the nuts that came with the collet set measured 1.180" ID. So I turned a piece

that would fit the chuck bore with an ID of 1.180" and single pointed 20 threads per inch in it. I made the part long enough to make

several nuts.

Next I made two cuts with the metal saw. I clamp them in a length of angle iron with a previous cut in it for the saw blade. I think I cut more on the opposite side of the blade than I do in the vice.

Canadian Tire had G96 cold bluing on sale for half price a couple months ago so I bought all four that they had. Its one of the better cold bluing's that I have used.

The end result. The block now butts up against the chuck so its gripped more securely. It probably did not matter as most of the work done in a

collet block is going to be small diameter and light cuts. It was just my OCD kicking in again.

The 5C collets have an odd sized thread 1.238" x 20 the nuts that came with the collet set measured 1.180" ID. So I turned a piece

that would fit the chuck bore with an ID of 1.180" and single pointed 20 threads per inch in it. I made the part long enough to make

several nuts.

Next I made two cuts with the metal saw. I clamp them in a length of angle iron with a previous cut in it for the saw blade. I think I cut more on the opposite side of the blade than I do in the vice.

Canadian Tire had G96 cold bluing on sale for half price a couple months ago so I bought all four that they had. Its one of the better cold bluing's that I have used.

The end result. The block now butts up against the chuck so its gripped more securely. It probably did not matter as most of the work done in a

collet block is going to be small diameter and light cuts. It was just my OCD kicking in again.