-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Magnetic Base

- Thread starter Susquatch

- Start date

Tool

MrWhoopee

Ultra Member

I'm just using one of these "sewing machine" lights on my SG (and 4x6 and chain grinder). It looks positively dainty compared to that beast.

What does the light look like?

30 LED Sewing Machine Light US PLUG Gooseneck Working Lamp With Magnetic Base | eBay

Sewing is a very delicate thing. When you use a sewing machine, you may need a LED lamp to illuminate, especially at night, to facilitate your sewing. This LED lamp with plug, of which switch on the back with a strong magnet, can be adsorbed on the sewing machine.

www.ebay.com

What does the light look like?

ChazzC

Ultra Member

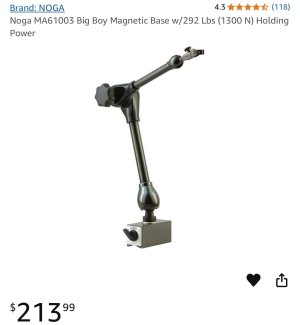

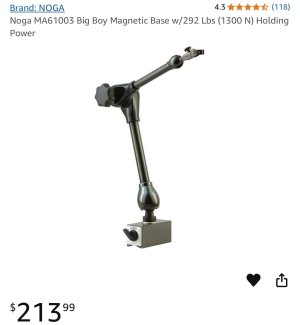

Looks like a Big Boy” base, rated at 1,300N (292 lbf); the arms & holder are rated for a 20kg load:

I have two that I use for photos & videos in a simpler setup than James:

I got mine from All Industrial last year for ridiculous sale prices/new customer discount/coupon/free shipping for around US$150. Only needed the arms for the second one, but with base was cheaper than just the arms so I didn’t argue.

I have two that I use for photos & videos in a simpler setup than James:

I got mine from All Industrial last year for ridiculous sale prices/new customer discount/coupon/free shipping for around US$150. Only needed the arms for the second one, but with base was cheaper than just the arms so I didn’t argue.

Looks like a Big Boy” base, rated at 1,300N (292 lbf); the arms & holder are rated for a 20kg load:

I'd hazard a WAG that the weakest link in all these units is that 1/4" stud. Even a thin lock nut would help. Some day I'd like to cobble up something better. Project 42f3b.....

ChazzC

Ultra Member

If you mean the connection between the Noga arm and camera mount, I used an internal toothed lock washer on mine. You’ll have to wait until both my arms can reach above my head so I can see what I did with the other connections.I'd hazard a WAG that the weakest link in all these units is that 1/4" stud. Even a thin lock nut would help. Some day I'd like to cobble up something better. Project 42f3b.....

If you mean the connection between the Noga arm and camera mount, I used an internal toothed lock washer on mine. You’ll have to wait until both my arms can reach above my head so I can see what I did with the other connections.

Nope, I mean the 1/4 inch stud at the mag base itself. The further you get from the indicator or the camera, the more rigidity matters. That puny little 1/4 inch stud couldn't be in a worse place. It's not that 1/4" is all that weak, it's that it's also a crappy design that can wiggle around like a post in a hole with no dirt. I favour a big flat base on the screw that provides more rigidity without a bigger screw. Fisso does a good job of this but could be even better.

ChazzC

Ultra Member

Per Stefan, the big problem at the arm/base connection is the paint on the base (starting at 5:00):Nope, I mean the 1/4 inch stud at the mag base itself. The further you get from the indicator or the camera, the more rigidity matters. That puny little 1/4 inch stud couldn't be in a worse place. It's not that 1/4" is all that weak, it's that it's also a crappy design that can wiggle around like a post in a hole with no dirt. I favour a big flat base on the screw that provides more rigidity without a bigger screw. Fisso does a good job of this but could be even better.

[also, the Big-Boy has an M10 stud 🙂 ]

Per Stefan, the big problem at the arm/base connection is the paint on the base (starting at 5:00):

Without watching the video (I'll do that later), I have zero problem accepting the paint as an issue. A simple big washer should clobber that problem.

Never saw a m10 stud on any holder. I wonder what it would take to upgrade existing 1/4 studs to M10 or 3/8?

Dan Dubeau

Ultra Member

Wow, that's a Maaag base.

ChazzC

Ultra Member

Just to clarify, the stud on the bottom of the arm and the hole in the Mag Base is M10. I know because the adapter I made so I could mount the Big Boy arms to a Kant Twist has an M10 hole (from a post with videos from back in September that I haven't completed; I guess since I can keyboard I can go ahead and get this finished):Without watching the video (I'll do that later), I have zero problem accepting the paint as an issue. A simple big washer should clobber that problem.

Never saw a m10 stud on any holder. I wonder what it would take to upgrade existing 1/4 studs to M10 or 3/8?

NOGA sells a similar clamp, but for three times what a 4" clamp cost me, plus I had the 12L14 stock.

Last edited: