So I've now confirmed I am not an electronics genius and I need some help.

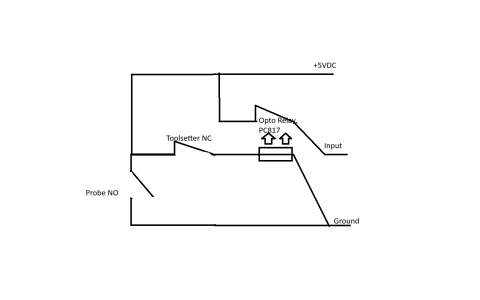

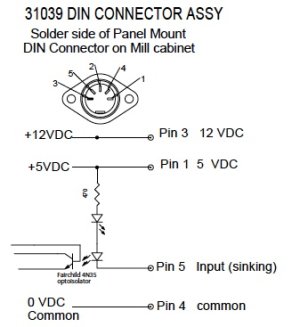

Situation- the Tormach has a single input for probes (toolsetters and touch probe), can be set active or passive in the PathPilot setting page.

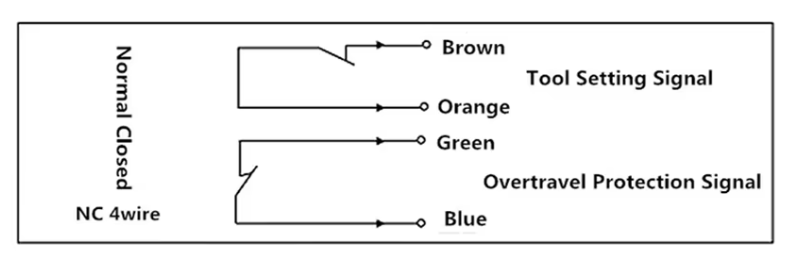

I have a tool setter that is "passive" (just a switch) and its configuration is NC - confirmed continuity when not trigger, open when triggered).

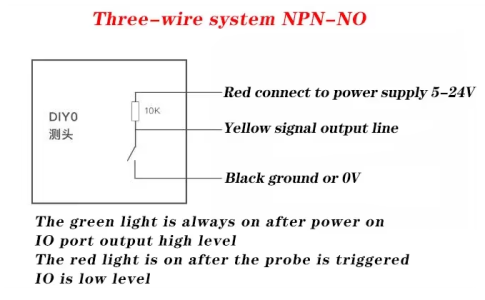

I just acquired a new touch probe that needs to share this input:

a) its an "active" sensor and outputs whatever the supply voltage is (works on 5v and 12V - even up to 24VDC) when not triggered and goes to 0v when triggered. Tested an works as an active probe in PathPilot.

b) its from China so no returning it for a different configuration

Was trying to figure out how to invert / switch one of the signals, but the thought just struck me now as I type this out:

Can I wire the new touch probe in series with the tool setter and effectively make the toolsetter active? The difference is that the output is just open when the toolsetter triggers as opposed to being pulled to ground...

Otherwise I need to get back to figuring out how to easily, cheaply combine these 2 signals - I could unplug one and plug in the other but that requires changing the settings in PathPilot and I know me - I'll screw it up sooner rather than later.

Situation- the Tormach has a single input for probes (toolsetters and touch probe), can be set active or passive in the PathPilot setting page.

I have a tool setter that is "passive" (just a switch) and its configuration is NC - confirmed continuity when not trigger, open when triggered).

I just acquired a new touch probe that needs to share this input:

a) its an "active" sensor and outputs whatever the supply voltage is (works on 5v and 12V - even up to 24VDC) when not triggered and goes to 0v when triggered. Tested an works as an active probe in PathPilot.

b) its from China so no returning it for a different configuration

Was trying to figure out how to invert / switch one of the signals, but the thought just struck me now as I type this out:

Can I wire the new touch probe in series with the tool setter and effectively make the toolsetter active? The difference is that the output is just open when the toolsetter triggers as opposed to being pulled to ground...

Otherwise I need to get back to figuring out how to easily, cheaply combine these 2 signals - I could unplug one and plug in the other but that requires changing the settings in PathPilot and I know me - I'll screw it up sooner rather than later.