So, while building my DG D&D knurling tool kit, I found I was....

Doing a lot of this..... It was time to make a dedicated DI fixture.

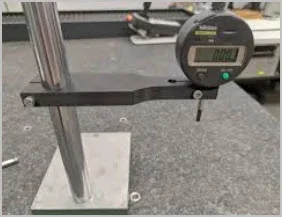

Basically a way clamp that allows a DI to be mounted. That knurled nut appears to secure it fine but if I find it doesn't, I'll drill it through and add a T handle.

Over all it's a bit of a compromise. I really wanted the DI dial facing up (or tilted up) and everything secured from above, but space constraints proved that impossible.

Craig

Doing a lot of this..... It was time to make a dedicated DI fixture.

Basically a way clamp that allows a DI to be mounted. That knurled nut appears to secure it fine but if I find it doesn't, I'll drill it through and add a T handle.

Over all it's a bit of a compromise. I really wanted the DI dial facing up (or tilted up) and everything secured from above, but space constraints proved that impossible.

Craig

Last edited: