Geoff

Member

I have been tooling up since I started machining, which was probably 1.5 years ago. As you all know, tooling isn't cheap and since I have a new addition to our family, i'm on a budget! Opposed to buying a bunch of tooling, I decided to start making various tool holders, arbors, and various other tools that are essential. I have stock so why not give it a try, right? These projects have been great with respect to getting time and experience on the machines and learning about various setups.

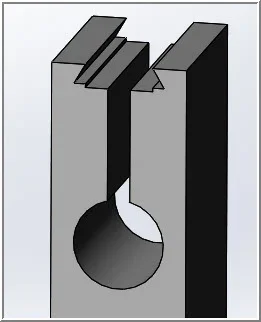

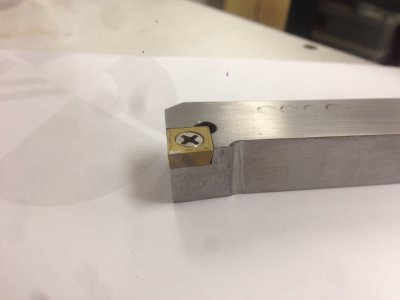

Thus far, I have made a few slitting saw arbors, insert tool holders, 3 jaw chuck key, face mill arbor, and a few others. I am currently making a R8 holder for 1" tooling (end mills or other cutting tools). My next projects will be an insert based 60 Deg. Dovetail cutter and then I will use that to make a bunch of QCTP holders. I have 2 of the standard QCTP holders and I am always changing the tools so about 4 more would be nice 🙂

Here are some pictures of the tooling that I have made and the R8 holder that I am currently working on. I'll add more pics this evening as I am missing some on my phone.

Thus far, I have made a few slitting saw arbors, insert tool holders, 3 jaw chuck key, face mill arbor, and a few others. I am currently making a R8 holder for 1" tooling (end mills or other cutting tools). My next projects will be an insert based 60 Deg. Dovetail cutter and then I will use that to make a bunch of QCTP holders. I have 2 of the standard QCTP holders and I am always changing the tools so about 4 more would be nice 🙂

Here are some pictures of the tooling that I have made and the R8 holder that I am currently working on. I'll add more pics this evening as I am missing some on my phone.

Attachments

-

Photo 1-2-2016, 5 06 00 PM.jpg910.7 KB · Views: 47

Photo 1-2-2016, 5 06 00 PM.jpg910.7 KB · Views: 47 -

Photo 1-2-2016, 11 27 13 AM.jpg711.1 KB · Views: 41

Photo 1-2-2016, 11 27 13 AM.jpg711.1 KB · Views: 41 -

Photo 1-10-2016, 11 38 24 PM.jpg846.1 KB · Views: 46

Photo 1-10-2016, 11 38 24 PM.jpg846.1 KB · Views: 46 -

Photo 1-11-2016, 10 28 02 PM.jpg712.5 KB · Views: 40

Photo 1-11-2016, 10 28 02 PM.jpg712.5 KB · Views: 40 -

Photo 10-31-2015, 9 39 16 PM.jpg1 MB · Views: 43

Photo 10-31-2015, 9 39 16 PM.jpg1 MB · Views: 43 -

Photo 10-31-2015, 9 39 25 PM.jpg732 KB · Views: 44

Photo 10-31-2015, 9 39 25 PM.jpg732 KB · Views: 44 -

Photo 12-27-2015, 12 27 12 AM.jpg768.4 KB · Views: 42

Photo 12-27-2015, 12 27 12 AM.jpg768.4 KB · Views: 42 -

Photo 12-27-2015, 12 29 08 AM.jpg759.9 KB · Views: 41

Photo 12-27-2015, 12 29 08 AM.jpg759.9 KB · Views: 41