Hi gang

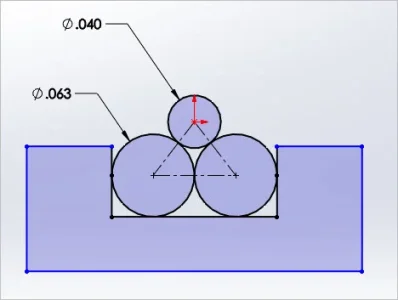

My mig welder has an option for knurled rolllers - the dealer wants $20 each and I need two plus shipping. $60 all in. This is for running flux core wire. A lot of money for such a simple part-except I don’t know how to make the tooth pattern. Any thoughts?

Thanks John

My mig welder has an option for knurled rolllers - the dealer wants $20 each and I need two plus shipping. $60 all in. This is for running flux core wire. A lot of money for such a simple part-except I don’t know how to make the tooth pattern. Any thoughts?

Thanks John