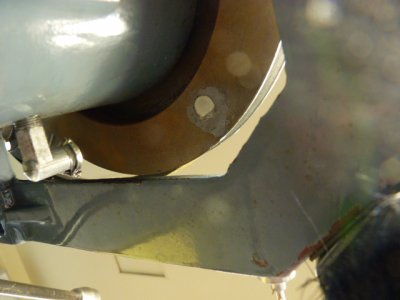

I finally got around to installing the lcd tach on my mill. Pretty straight forward and no surprises, I was able to drill the recess for the magnet without removing the pulley. I used JB Weld to hold the magnet in place.

Next was make the bracket for the for the sensor, 1/8 alum, and position it under the magnet.

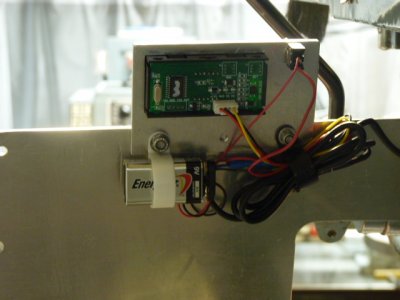

The bracket for the display and the on/off switch (power) is also 1/8 alum, all the cutting and drilling was done on the mill. Then I mounted the bracket to the top of notepad board. All the wiring was bench tested to make sure it worked and the magnet would be mounted correctly. Success!

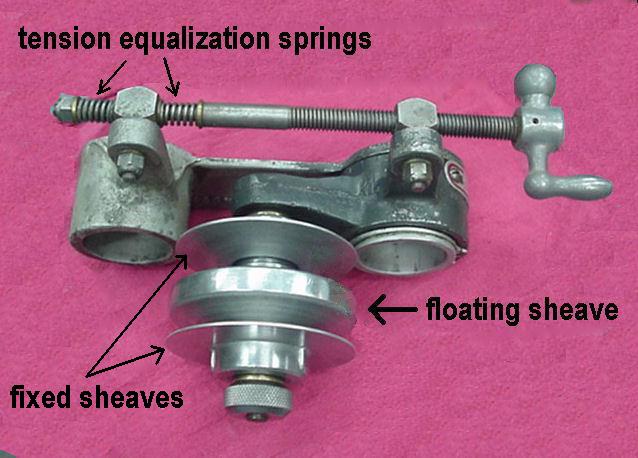

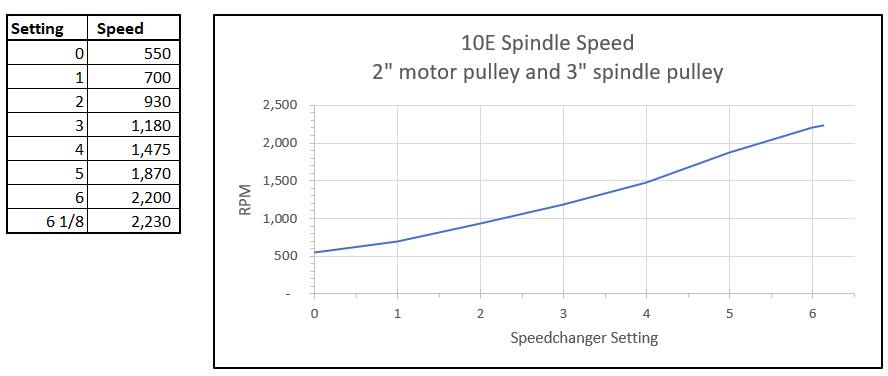

My mill doesn't have a belt combination that gets in the 600rpm range, it was mentioned in another thread to try direct drive from the motor to the spindle, BINGO, I was able to get a 540rpm and a 650rpm which is perfect for a .500EM. The advantage to a link belt is being able to easily vary the length and it will do the minor bend around the middle pulley without flying off.

Now if I do go to a VFD and 3Ph motor I'm ready for the speed changes.

Next was make the bracket for the for the sensor, 1/8 alum, and position it under the magnet.

The bracket for the display and the on/off switch (power) is also 1/8 alum, all the cutting and drilling was done on the mill. Then I mounted the bracket to the top of notepad board. All the wiring was bench tested to make sure it worked and the magnet would be mounted correctly. Success!

My mill doesn't have a belt combination that gets in the 600rpm range, it was mentioned in another thread to try direct drive from the motor to the spindle, BINGO, I was able to get a 540rpm and a 650rpm which is perfect for a .500EM. The advantage to a link belt is being able to easily vary the length and it will do the minor bend around the middle pulley without flying off.

Now if I do go to a VFD and 3Ph motor I'm ready for the speed changes.