TorontoBuilder

Sapientia et Doctrina Stabilitas

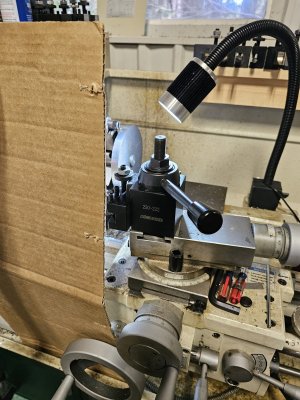

Watching a video trying to learn a bit more and I see the fellow place this paper with a cut out on his workpiece.

Behind it is a steady rest.

So is the paper to keep swarf from getting on the workpiece and then getting stuck in the bearings?

Behind it is a steady rest.

So is the paper to keep swarf from getting on the workpiece and then getting stuck in the bearings?