Robert Gallagher

New Member

Hi,

I just purchased a Mini lathe.

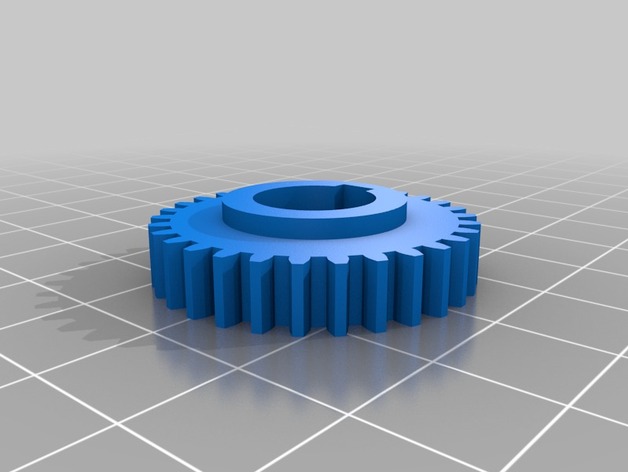

I have never understood how to install the différent gear for thread shaping. Exemple: I need to make 3/8-24 thread; the label indicate that you need a 40T on the A spindle and a 60T on the D spindle. My understandind is no gears are needed on spindle B and C. When I go that route, gears A and D cannot engage.

what am I doing wrong here?

Thank you in advance.

I just purchased a Mini lathe.

I have never understood how to install the différent gear for thread shaping. Exemple: I need to make 3/8-24 thread; the label indicate that you need a 40T on the A spindle and a 60T on the D spindle. My understandind is no gears are needed on spindle B and C. When I go that route, gears A and D cannot engage.

what am I doing wrong here?

Thank you in advance.