I was reluctant to post this because it is a bit hard to explain and show but I have often found there is such good ingenuity and experience on this forum that I figured I would try anyhow.

I'm attempting to put on an oil cooler on a 250cc motorcycle that wasn't really designed for an oil cooler. The engine however does have oil ports that allow me to tap into for intake and outake. I'm using an aftermarket generic oil cooler.

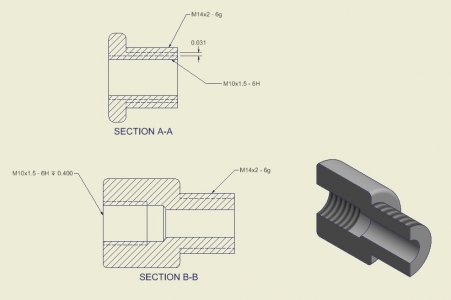

The oil cooler fittings are 10mm but the engine oil ports are 14mm. I have to somehow adapt the hose fitting to the 14mm oil port.

The easiest would be to bore out the hose fitting to accept a new 14mm oil passage bolt but I don't think there is enough clearance for that to happen and still have acceptable oil flow through the fitting.

My next thought is if I should make a new 10mm oil passage bolt that fits the hose fitting but then make a thread adapter that has 10mm internal threads and 14mm external threads. I'd loctite this adapter on the oil passage bolt once it was through the hose fitting.

The other option I can think of would be to make some sort of 14mm threaded hose barb/nipple that would go directly from engine port to bare hose. It would have to be a 90 degree attachment to keep the hose from protruding too far away from the engine.

Any thoughts or suggestions?

I'm attempting to put on an oil cooler on a 250cc motorcycle that wasn't really designed for an oil cooler. The engine however does have oil ports that allow me to tap into for intake and outake. I'm using an aftermarket generic oil cooler.

The oil cooler fittings are 10mm but the engine oil ports are 14mm. I have to somehow adapt the hose fitting to the 14mm oil port.

The easiest would be to bore out the hose fitting to accept a new 14mm oil passage bolt but I don't think there is enough clearance for that to happen and still have acceptable oil flow through the fitting.

My next thought is if I should make a new 10mm oil passage bolt that fits the hose fitting but then make a thread adapter that has 10mm internal threads and 14mm external threads. I'd loctite this adapter on the oil passage bolt once it was through the hose fitting.

The other option I can think of would be to make some sort of 14mm threaded hose barb/nipple that would go directly from engine port to bare hose. It would have to be a 90 degree attachment to keep the hose from protruding too far away from the engine.

Any thoughts or suggestions?