mickeyf

Ultra Member

Short question:

How would you cut an axial slot all the way through the wall of a very thin walled cylinder?

Longer version:

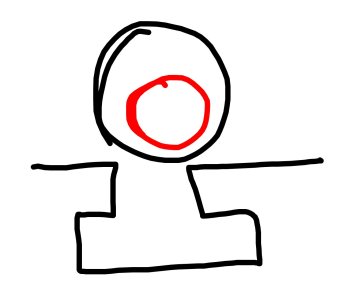

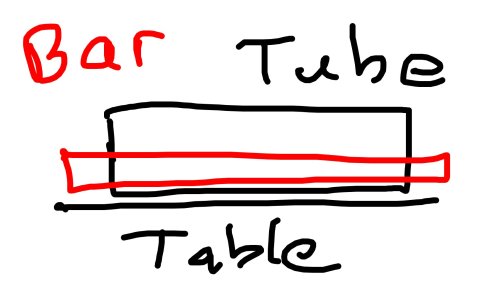

I’m replacing a single phase motor on a drill press with a 3 phase motor and VFD. The shaft on the original motor and pulley bore are 5/8”, the new motor shaft is 12mm, slightly smaller. Simple enough, make a sleeve. So I did, allowing about ½ a thou larger in the bore of the sleeve for a snug push fit, and ½ a thou less on the outside diameter for a similar fit in the DP pulley.

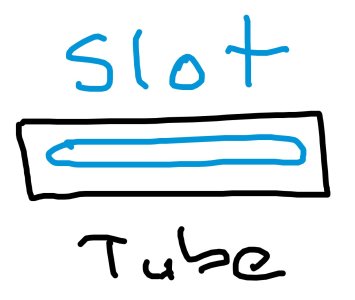

But I didn’t want to lose the keyway, and the wall thickness of the sleeve is less than 2 mm. I didn’t see likely success by cutting the keyway either before boring the inside or turning down the outside of the sleeve – even with a very light cut I was afraid that interrupted cut would grab.

What I finally did was to make a sacrificial plug the same diameter as the shaft the sleeve would slide onto, and a hair shorter so that the sleeve itself rather than the plug would be gripped by the vice when cutting the keyway. I was also nervous about the rotational force of an end mill causing issues. A woodruff cutter would have been better than an end mill (or doing it on the shaper) since all the cutting force would have been axial to the sleeve, but that would have required an awkward setup on a vertical mill.

I did it, it worked, but I’m wondering what other approaches might have been taken?

How would you cut an axial slot all the way through the wall of a very thin walled cylinder?

Longer version:

I’m replacing a single phase motor on a drill press with a 3 phase motor and VFD. The shaft on the original motor and pulley bore are 5/8”, the new motor shaft is 12mm, slightly smaller. Simple enough, make a sleeve. So I did, allowing about ½ a thou larger in the bore of the sleeve for a snug push fit, and ½ a thou less on the outside diameter for a similar fit in the DP pulley.

But I didn’t want to lose the keyway, and the wall thickness of the sleeve is less than 2 mm. I didn’t see likely success by cutting the keyway either before boring the inside or turning down the outside of the sleeve – even with a very light cut I was afraid that interrupted cut would grab.

What I finally did was to make a sacrificial plug the same diameter as the shaft the sleeve would slide onto, and a hair shorter so that the sleeve itself rather than the plug would be gripped by the vice when cutting the keyway. I was also nervous about the rotational force of an end mill causing issues. A woodruff cutter would have been better than an end mill (or doing it on the shaper) since all the cutting force would have been axial to the sleeve, but that would have required an awkward setup on a vertical mill.

I did it, it worked, but I’m wondering what other approaches might have been taken?