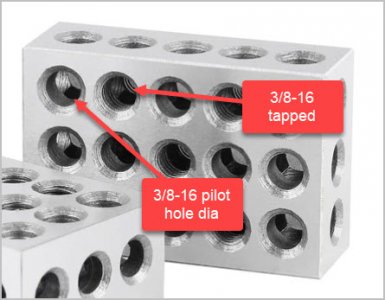

Ok I bought four of these basic 123 blocks from accusize. All the holes were drilled to tap ( they measure about .355”) so they are too small to pass a .375 ready rod or bolt through. I thought maybe I can drill them out. They are hardened though. Regular drill bit no not at all. I tried a used carbide bit I have. Chowdered it after about half way through one hole. So …

I had one thought to anneal it - maybe in a aluminium foil bag? Then drill and then reharden them? Or is this just going to create loads of oxides and ruin the surface so it’s no longer accurate?

Looks like the server won’t upload larger files again I’ll see what we can do about that.

I had one thought to anneal it - maybe in a aluminium foil bag? Then drill and then reharden them? Or is this just going to create loads of oxides and ruin the surface so it’s no longer accurate?

Looks like the server won’t upload larger files again I’ll see what we can do about that.