I've been handed a project where I need to make maybe 30 U-shaped bends in 5/16" solid rod. The radius will be about 6 inches, with straight legs about 12"-14" long

I have a bench mounted ring roller and a floor mounted bender. Also have oxy/propane.

The stated capacity of the ring roller is 1/4" and the floor mounted bender is too small to make a 6" radius bend.

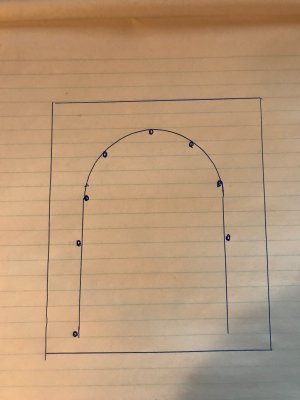

I was thinking of making a jig, basically a plate with some means to secure the stock while the free end is curved around.

Having never bent 5/16' rod I have no idea how much force might be needed.

I have a bench mounted ring roller and a floor mounted bender. Also have oxy/propane.

The stated capacity of the ring roller is 1/4" and the floor mounted bender is too small to make a 6" radius bend.

I was thinking of making a jig, basically a plate with some means to secure the stock while the free end is curved around.

Having never bent 5/16' rod I have no idea how much force might be needed.