Dan Dubeau

Ultra Member

One, but I probably could have got another one in there if he had one.

Was a bit of a struggle getting it out on my end, but eventually got it onto a hand truck, and into it's new temporary home.

came with a bit of tooling too. That is a dickson toolpost, and 5 holders.

And the cutest little boring head I've ever seen. That little grinding vise is aluminum.

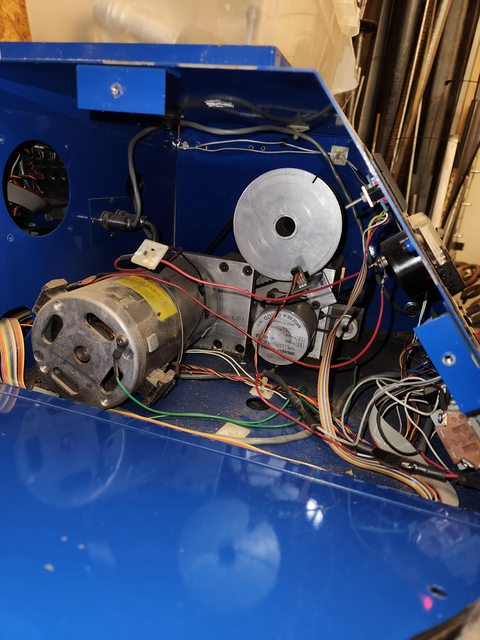

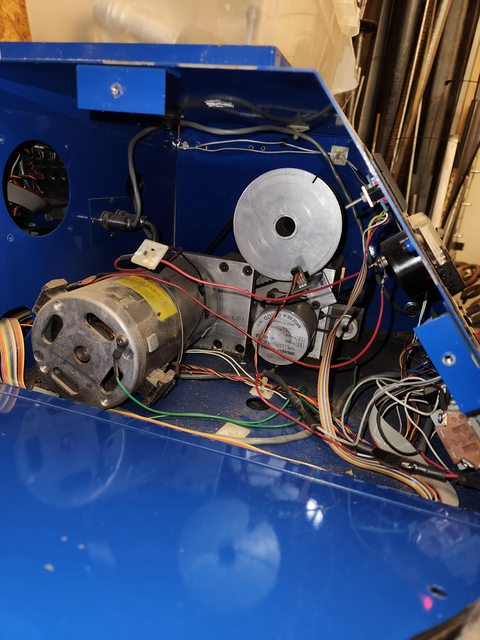

It will power on, and the RPM gauge will read the encoder if you spin the chuck by hand in manual mode, but there are no combinations of buttons, and switch presses that will make it move or home. No manual with it, but have found some info online. I figured on a complete retrofit anyway even before I bought it, but will give it a good shot to try and get it running with what's there. Not sure if it needs a computer connection and software to home and run, but it looks like it. I will look into it a bit more tonight to see what I can find.

Not expecting much out of it as far as being a lathe, it's pretty light duty, but it should be a fun project to play around with.

Was a bit of a struggle getting it out on my end, but eventually got it onto a hand truck, and into it's new temporary home.

came with a bit of tooling too. That is a dickson toolpost, and 5 holders.

And the cutest little boring head I've ever seen. That little grinding vise is aluminum.

It will power on, and the RPM gauge will read the encoder if you spin the chuck by hand in manual mode, but there are no combinations of buttons, and switch presses that will make it move or home. No manual with it, but have found some info online. I figured on a complete retrofit anyway even before I bought it, but will give it a good shot to try and get it running with what's there. Not sure if it needs a computer connection and software to home and run, but it looks like it. I will look into it a bit more tonight to see what I can find.

Not expecting much out of it as far as being a lathe, it's pretty light duty, but it should be a fun project to play around with.