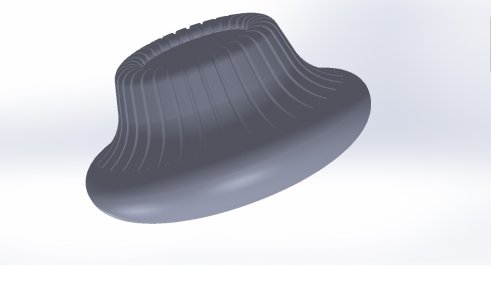

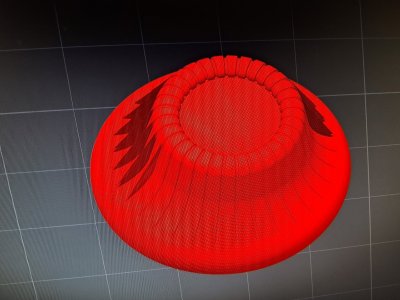

My neighbor asked if I could 3D print a couple of radio knobs for her old Electrohome 216B radio. After seeing the knob my CAD side of my brain started whirling along thinking about how I was going to sketch this up. The lazy doughnut side of my brain starting thinking that looks like a lot of work. How the hell did they do this back in the day. It is wood with a brass insert( with a set screw.....you can just see the hole for it in the bottom view). The bottom curve of the knob follow the shape of the tray that it is set in. It's the curved splines that are tapered as they come from the base of the knob up to the top that has me wondering? These would have been mass produced back in ~1940 in Kitchener, Ontario.

I did make a post on canadianvintageradio.com incase someone has these in their collection of parts. They are pretty unique.

Cheers, P.

I did make a post on canadianvintageradio.com incase someone has these in their collection of parts. They are pretty unique.

Cheers, P.