Also, consider that many parts can be built as an assembly, and glued together. ABS, ASA and even PLA bond very well when using acetone (ABS) or PVC pipe cleaner (PLA etc). Not many plastics bond well with epoxy, but if you can find methylmethacrylate adhesive it will bond anything very permanently, including metals, nylons and acetyl.

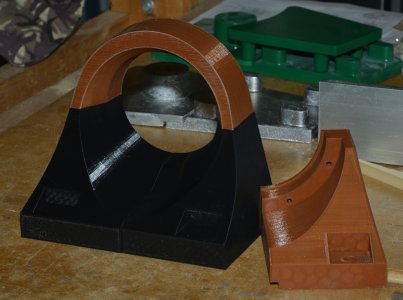

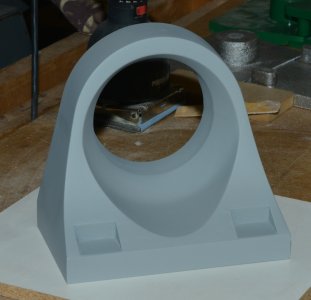

So with a bit of forethought, some designs can be split into blocks, printed independently (colour, material, fill density) and bonded together.

As @jcdammeyer said, using 3DP as part of the design can solve many of the complex geometry/milling/fabrication/strength issues and this is what I find makes the technology so useful.

🙂

So with a bit of forethought, some designs can be split into blocks, printed independently (colour, material, fill density) and bonded together.

As @jcdammeyer said, using 3DP as part of the design can solve many of the complex geometry/milling/fabrication/strength issues and this is what I find makes the technology so useful.

🙂