-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

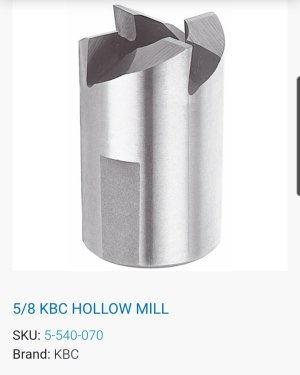

Tool Hollow mill

- Thread starter motordr

- Start date

Tool

Megar arc 5040dd

Super User

Do you mean like an annular cutter?Looking to buy a hollow mill, 5/8” diameter. Any help appreciated.

Looking to buy a hollow mill, 5/8” diameter. Any help appreciated.

No idea what you are asking. A drawing or a better description would help.

It’s an end mill that is hollow and cuts on the inside only to a precise diameter, so if you have something like a worn 1” diameter steering ball an a Model A Ford front spindle, you could machine off the worn portion and be left with a 5/8” diameter stub. It’s not a spot racer or hole saw. KBC lists it but has no stock.

It’s an end mill that is hollow and cuts on the inside only to a precise diameter,

I see. Closest thing to that I can think of is an "annular cutter". Properly held with a solid work clamp and nothing to steer them off axis, they work really well. They cut a nice hole on both inside and outside. They also make some funky swarf. You can buy them on amazon for next day delivery.

If you post a link to the KBC product, I could also look at other sources for you.

Unfortunately, it's listed, 'no longer available', from KBC. I think KEO makes them as well. I've had to make a couple for small diameters out of 01 tool steel.Looking to buy a hollow mill, 5/8” diameter. Any help appreciated.

Attachments

Unfortunately, it's listed, 'no longer available', from KBC.

Hey Stel, what are the advantages of that over an annular cutter?

My two cents are that your hollow endmill would jam up with swarf FAST! I think swarf elimination is a huge advantage for Annular Cutters.

The hollow mill cutter has a large relief bore behind the flutes. I don't think they're really designed for a plunge cut like an annular cutter, but are more for machining a slightly oversized shaft to finish outside dimension on a part that you can't machine normally, like with a boring bar.

In the photo is a pair of extractors for a side by side shotgun. The two halves would be soft soldered together, then the hollow mill would machine the 'tail' to proper dimension, then separated. As you can see, the tail is 2.75" in length, and there's no way you're going to fit a boring bar between the 'tail' and guide pins. And the tail would be too flexible to cut with a single point tool.

The smallest annular I've seen is 7/16", so the hole is? 1/4"? The one I have is 3/32"

The small one I made is to face the bottom of a front bead slightlt so that it will point straight forward.

In the photo is a pair of extractors for a side by side shotgun. The two halves would be soft soldered together, then the hollow mill would machine the 'tail' to proper dimension, then separated. As you can see, the tail is 2.75" in length, and there's no way you're going to fit a boring bar between the 'tail' and guide pins. And the tail would be too flexible to cut with a single point tool.

The smallest annular I've seen is 7/16", so the hole is? 1/4"? The one I have is 3/32"

The small one I made is to face the bottom of a front bead slightlt so that it will point straight forward.

Attachments

I don't think they're really designed for a plunge cut like an annular cutter, but are more for machining a slightly oversized shaft to finish outside dimension on a part that you can't machine normally, like with a boring bar.

That makes sense. Especially in light of the OP's request. Nonetheless, I find that annular cutters usually leave a decent finish on the stub.

I've never used annular cutters...yet. I understand they cut a pretty accurate and smooth hole, but what does the plug look like? Probably not so nice or accurate. In essence that's the purpose of using the hollow mill, to create an accurate and smooth "plug".That makes sense. Especially in light of the OP's request. Nonetheless, I find that annular cutters usually leave a decent finish on the stub.

TorontoBuilder

Sapientia et Doctrina Stabilitas

5/8" shank, or hole?Looking to buy a hollow mill, 5/8” diameter. Any help appreciated.

TorontoBuilder

Sapientia et Doctrina Stabilitas

I'd use the term "stud" over plug and then people may better understand the purpose of the tool.I've never used annular cutters...yet. I understand they cut a pretty accurate and smooth hole, but what does the plug look like? Probably not so nice or accurate. In essence that's the purpose of using the hollow mill, to create an accurate and smooth "plug".

@thestelster - Here is a core from an annular cut in a 2x4" thick aluminium bar. The core is about 1.4 inches in OD. I believe the OD was 2 inches as well. It's a long ways away from perfect but not really that bad either. It wouldn't take much to clean it up. Steel cores seem to be better. Last but not least, it was done with a 2" long cutter so it had to be pulled out periodically to clear internal swarf that would have prevented a full depth cut. This is a reality that I hadn't expected because the external swarf is just wow!

I like using annular cutters because they leave useful pieces of stock behind.

I like using annular cutters because they leave useful pieces of stock behind.

TorontoBuilder

Sapientia et Doctrina Stabilitas

There is more than one way to skin a cat as they say.View attachment 56000So this is the setup, used a boring head since no access to the hollow mill.

Thanks for teaching me about hollow mills.